Advances in cutting with ultrahigh-power fiber lasers

Ultrahigh-power (UHP) fiber lasers in the range of 10 to 40 kW have seen rapid adoption for cutting during the past few years, and the maximum laser power used for cutting is expected to continue to climb. We present cutting application results within this range and discuss the main factors driving the use of UHP fiber lasers, namely their remarkable productivity advantages, cut quality gains, and increased thickness capability (e.g., 230-mm-thick steel cutting shown in this article at 40 kW).

UHP lasers are defined here as greater than 10 kW of power, and they enable new process regimes to facilitate the expansion of laser cutting into new markets (e.g., by cutting up to 50 mm steels 4x faster than high-power plasma using air-assist gas). Application results show UHP lasers are changing the way steel is cut by replacing nitrogen and oxygen cutting processes with the air-assist process for high-quality and high-speed economical cutting.

Laser cutting has been marked by periods of intense technological advancements since its inception about 50 years ago, namely the introduction of commercial laser cutting machine tools in the 1970s and their use in mass production by early adopters. This was followed by the expanded adoption of carbon dioxide (CO2) laser cutting systems in 1980s, and the introduction of high-power fiber lasers in the late 1990s and early 2000s. During the late 2000s, the development of kilowatt-level fiber laser cutting tools enabled laser cutting to migrate away from specialized niche applications to become a mainstream fabrication process. Fiber laser cutters dominated the market for laser cutting of sheet metals, mainly due to their ease of integration, reliability, low maintenance, relatively low capital and running costs, high cutting throughput, and the feasibility of scaling their power.

In the late 2010s and early 2020s, the path for market growth of laser cutting took two directions. One trend is across the low-power end of the market, with surging demand for 1–3 kW cutters, driven by a lowered equipment capital cost. The second trend is in the high-power end of the market, which has also seen increasing demand for UHP lasers. This is being driven by their high productivity and technological capabilities offered at an economical price, and the laser cutting field has experienced a remarkable power transformation that is unparalleled among other sheet metal manufacturing processes during the same period. Maximum laser power offered on cutting machine tools at fabrication tradeshows has risen from 6 kW in 2015 to an expected 40 kW in 2022, a nearly 7X increase (see Fig. 1 at top of this page). In the last three years alone, the available system power has climbed from 15 kW to 40 kW—a 2.5X surge.

Why now?

Reliable high-power fiber lasers were available several years before the UHP cutting trend started, with 100 kW industrial fiber lasers available as early as 2013.1 But it was only after the rapidly declining price per kilowatt of lasers within the past few years that the barrier to entry into UHP laser cutting was reduced. Cutting heads to reliably handle such high optical power levels within the harsh cutting environment also became available, as well as cutting libraries for UHP cutting systems.

Test setup

For the tests presented here, IPG YLS-40000 40 kW and IPG YLS-30000-ECO2 30-kW high-wall-plug efficiency fiber lasers were used, set up with 100 µm fiber core diameter and the IPGCut-HP cutting head to assess the cutting speed and quality in different metals. To the extent of the authors’ knowledge, 40 kW laser power in 100 µm fiber core diameter is the highest level of laser source intensity ever used to date for industrial laser cutting. We selected a 100 µm fiber core diameter because of the additional 10–25% increase gained in cutting speed compared to 150 µm diameter.

Higher cutting speeds

Our experiments show laser cutting speed increases with increasing average power up to 40 kW for all metals tested, including stainless steel, carbon steel, and aluminum. Figure 2 shows the increase of cutting speed vs. laser power within the range of 12 to 40 kW, for 6–40 mm carbon steel with air-assist gas. The percentage gain in speed increases with increasing metal thickness. For example, a 280% increase in cutting speed for 12-mm-thick carbon steel from 15 to 40 kW (a 270% increase in power) is observed, while a 420% increase is observed for 20-mm-thick carbon steel. For 30 mm carbon steel, going from 30 to 40 kW (a 33% power increase) leads to 66% faster cuts. This suggests that UHP lasers with even higher power may lead to further productivity gains in thick cutting.

To harness the high cutting speed that UHP lasers provide to achieve a significant reduction in cycle time, it is important to cut parts at high accelerations, especially for thinner materials. In recent years, the acceleration limit on typical machines has shifted from 1 g to 3 g to cope with higher laser powers. On the high end, UHP laser cutters with accelerations as high as 6 g were introduced, along with mechanical designs to support such forces without significant path deviations.

Lowering cost per part for fast return on investment

UHP laser cutting (vs. lower power) significantly reduces the cost per part and leads to a fast return on investment and higher profitability. In laser cutting, a major contributor to the operating cost is gas consumption, and gas costs tend to increase significantly with part’s thickness.

UHP laser cutting requires the same or less gas pressure and nozzle size as lower-power cutting. But the cutting speed increases dramatically, which reduces the cutting time per part and substantially reduces gas consumption. For example, a 30 kW laser can cut a typical 16-mm-thick stainless steel part in half the cycle time compared to a 15 kW laser—cutting gas consumption in half.

The electricity consumption of the laser and chiller typically grows linearly with power. Despite that, the electricity consumption of the rest of the cutting machine tool remains about the same. Therefore, with half the cycle time per part in the previous example, we lower the overall electricity costs per part with increased laser power. With continuous developments, high-power fiber lasers’ energy efficiency exceeds 50% and further contributes to electricity savings.2

Factors other than faster cutting also contribute to gas savings with UHP lasers. UHP lasers allow for fast, dross-free cutting of thick carbon steel with high-pressure air, compared to the use of more expensive nitrogen or much slower oxygen cutting. In both nitrogen and air cutting, UHP allows for reduction of gas pressure needed for dross-free cuts. For example, for dross-free cuts in 20-mm-thick carbon steel at 15 kW, air pressure higher than 16 bar is needed, while 10–12 bar will be sufficient at 20 kW or higher. Since gas usage roughly varies linearly with pressure (at the same nozzle size), significant pressure reduction contributes to gas savings and eases the specification of gas generation equipment.

A high-power laser cutting system with twice the productivity vs. lower power is not twice as expensive. This is because the cost per kilowatt decreases with increasing laser power. In addition, the higher laser cost is absorbed in the total machine tool cost, which can have a marginal increase vs. a lower power laser tool. Therefore, it is not surprising to see a UHP laser cutter with 2x productivity gained by higher laser power with only 30–40% higher capital cost.

With significantly higher productivity, one UHP system can replace multiple lower-power systems, requiring a proportionally smaller footprint, fewer operators, and fewer facility preparations. On the other hand, the reliability requirements for UHP fiber laser sources and cutting heads are higher to maintain productivity. Namely, for the fiber laser source, stable power output and beam quality over the long term is required, driven by the quality of diodes, components, and optical integration. As for the UHP cutting head, it should handle high optical power, high-pressure gas, dust, process heat, and high acceleration for reliable operation.

New process options for cutting steel

Carbon steels can be cut with oxygen, nitrogen, or air-assist gas. Figure 3 summarizes the pros and cons of using each assist gas. While oxygen cutting excels at cutting thick carbon steel with lower laser power due to additional oxidation energy, it can become a productivity hindrance, because its speed does not scale well with laser power. On the contrary, air cutting of carbon steel scales well with power (see Fig. 2). For example, for 16-mm carbon steel, oxygen cutting speed remains flat from 10 to 30 kW, around 2 m/min, while the air cutting speed at 30 kW rises to higher than 9 m/min, which is 4.5x faster than with oxygen.

Thicknesses exclusively cut with oxygen at lower power and lower speed can now be processed several times faster and with good quality using UHP lasers and air. For low-power lasers, air cutting results in hard-to-remove dross and an undesirable surface quality. Development of this new high-productivity UHP fabrication option has been enthusiastically accepted by industries that heavily rely on thick steels, such as manufacturing construction equipment and heavy industry applications.

Contact White Dog Engraving

For engraving in the DFW area, contact White Dog Engraving today by calling (972) 848-7790 or click here to connect with us online.

Benefits of Using a Laser-Cutting and Engraving Service

Custom laser-cutting and engraving services are an excellent choice for businesses needing a range of cut-out or engraved products, from signage and displays to greeting cards. Lasers can cut and engrave many materials, including plastic, cardstock and paper, plywood, solid wood, wood veneer, and even fabrics.

Before the use of lasers, jobs that required cutting and engraving materials were done by hand. As a result, these jobs were challenging and often resulted in poor-quality products, inconsistent results, and extensive turnaround times. With lasers, however,customers enjoy a consistently high-quality product and a quick completion time. But what contributes to this level of quality and consistency, and why should your business go with a reputable laser cutting company such as Laser Cutting, Inc.?

1. Precision

Lasers used in laser-cutting and engraving are extremely accurate and can be adjusted to ensure the ideal cut or mark on a specific material. In fact, lasers are accurate to within one nanometer in both cutting and engraving. No other form of cutting and engraving is that precise—especially when the cutting and engraving is done by hand. In addition, the precision of a laser results in a reliably crisp and clean-looking product that sets your company apart and gives you an edge over the competition. Just imagine the professionalism and appeal a sleek laser-cut sign will add to your storefront, or the awe an intricately-cut textile display will inspire in your customers.

2. Cost-Efficiency

Having

your new acrylic signage, paper invitation cards, or custom wooden mural cut

and engraved with lasers is far more cost-effective than having these services

done by hand. You’ll not only receive a meticulously crafted product at a

better value, but also enjoy a shorter turnaround time. This quick production

time cuts down on cost.

In addition, laser-cutting and engraving is a cost-efficient alternative to other manufacturing methods for small businesses, schools, and even crafters. Crafters, for example, utilize laser-cutting and engraving for custom cards, mosaics, and woodworking. Schools may use these services to produce custom murals, mylar stencils for lettering, logos, and signage. More and more small businesses are using laser-cutting and engraving to manufacture anything from a single item to a large-volume order.

3. Shorter Turnaround

As stated before, laser-cutting companies offer a shorter turnaround time than conventional cutting and engraving services. This stems from the fact that lasers cut through materials more quickly and accurately than other cutting methods, including routers, milling machines, and mechanical cutting processes. Due to computer programming and automation, laser-cutting is also highly customizable. This means that the process isn’t just fast—it’s also highly precise, even for extremely complex designs.

Contact Us

At White Dog Engraving, we provide engraving services for the DFW area. To learn more about the services we can offer you, contact us today by clicking here.

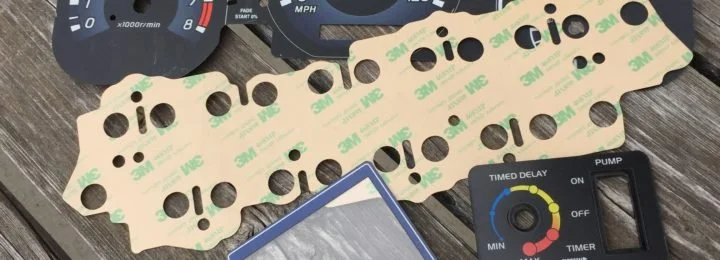

Laser Engraving Leather Debossing Stamps with MDF and Acrylic

Laser Engraving Leather Debossing Stamps with MDF and Acrylic

Since we’ve engraved away a lot of material to achieve our desired depth, our stamps are quite dirty. We’ll take these back to our sink and scrub away that residue.

We recommend limiting your MDF stamp’s exposure to water while cleaning. MDF is absorbent and significant amounts of water can cause it to break down. Our stamp was exposed to water only briefly and it has held up very well, but your mileage may vary. To be safe, you can opt to clean your MDF stamp with a dry or damp brush.

Once we’re done, we’ll also peel off our protective masking.

Soaking our Patches

The last bit of prep involves soaking our leather patches. This may not be necessary for every material, but with these patches we found soaking them in water prior to debossing made them much more pliable and more receptive to the stamping process. This didn’t take long though; we soaked our patches for around a minute.

Debossing

Now it’s time to put our stamps to the test.

In order to get a nice, deep impression, we’ll need to press the stamp into the leather very firmly. We’ll use several clamps to accomplish this, but a vice would also work very well. We’ll use a couple of wood blocks to protect our materials from the clamps and to evenly disperse the pressure.

We’ll apply this pressure for a brief but sustained period of time (several minutes or so should do the trick), then we’ll release the clamps and see our results.

As you can see, both the MDF and the acrylic provided excellent results with these patches. Both materials gave us a great quality mark, so feel free to experiment with the materials you use. Acrylic is a more expensive option, but using clear acrylic meant we could see through the graphics on our stamp, making it even easier to align our images with confidence. You could try using wood or Delrin, or even metal if you’re using a fiber laser.

We applied some leather conditioner to our debossed patches to help finish them off and provide a bit more contrast. If you’re working with raw leather, you could also consider using some leather dye. Really, the sky’s the limit; let your creativity shine.

Contact White Dog Engraving

To learn more about the engraving services we can offer you, contact us today by calling (972) 848-7790 or click here to connect with us online.

The Best Solution for Laser Engraving Polyethylene

Searching for a laser engraving machine that will work with polyethylene? Look no further than the laser engraving systems from TYKMA Electrox. Below, we’ll look at specifics for polyethylene along with our recommended system for marking it, the Vereo UV Integration Laser.

About Polyethylene

Laser systems from TYKMA Electrox are capable of engraving various materials and substrates, including polyethylene. Polyethylene is the most common plastic in the world and is extremely versatile. It can be found in all of the following and much more:

Plastic grocery bags

Injection moldings

Shampoo bottles

Bulletproof vests

Medicine jars

Children’s toys

Water bottles

Wire insulation

Peanut butter jars

Drainpipes

Plastic containers

Tubing

Gasoline containers and tanks

Coatings and laminations

Fishing and sports nets

Telecommunication cables

While polyethylene has various applications, it is most commonly used in industrial, marine, municipal, mining, duct, landfill, and agricultural applications. Some features of polyethylene that makes it such a versatile and valuable material for companies are as follows:

Light weight

Tough

Good moisture resistance

High chemical resistance

Low coefficient of friction

Easy to process

Good corrosion resistance

Polyethylene is available in several grades and formulations but is classified into five main categories according to its density. These five main categories of polyethylene are as follows:

Low density

Linear low density

High density

Ultra-high-molecular-weight

Cross-linked

Additionally, polyethylene can vary between being transparent, translucent, and opaque depending on its thermal history and thickness.

The Vereo UV Integration Laser

As a leading provider of laser marking systems, TYKMA Electrox offers a number of laser engraving machines. However, some machines are better for engraving specific materials than others.

In particular, we recommend our Vereo UV Integration Laser for marking polyethylene, as UV lasers are more suited for this material than fiber lasers.

Our Vereo UV Integration Laser is a highly efficient system that is air-cooled and maintenance-free, while featuring low energy consumption.

Some of the system’s diverse applications include:

Marking polyethylene

Marking silicon

Black annealing on medical devices

Glass scribing

Be sure to visit our Vereo UV Integration Laser page linked above for full product specs.

The Benefits of Laser Engraving Polyethylene

Some of the benefits of laser marking polyethylene include:

Polyethylene withstands extreme UV exposure and substantial salt spray testing

High contrast marking is possible on any color of polyethylene

Laser marks on polyethylene are clear, distinct and precise

Additionally, we accept materials for application testing and evaluation. Reach out to us today to see the effects of laser marking polyethylene, free of charge!

More Laser Marking Systems from TYKMA Electrox

With the laser marking systems from TYKMA Electrox, laser engraving has never been easier. Whether you need to engrave a logo, 2D code, barcode, or identification number, a laser engraving system from TYKMA Electrox has got you covered.

All TYKMA Electrox laser engraving systems are equipped with the following:

Top-of-the-line laser engines with an extensive lifespan

Energy-efficient operations and advanced capabilities for etching, marking, and engraving

Air-cooled, ergonomic designs

User-friendly controls and cutting-edge features

Additionally all of our laser marking machines are shipped fully assembled and require no calibrations. Backed with the best warranty in the industry, our laser marking systems are used in a wide variety of industries.

More

Contact White Dog Engraving

At White Dog Engraving, we specialize in engraving services for the DFW area.

To learn more about the services we can offer you, contact us today by clicking here.

Unique Wedding Gift Ideas For The Couple Who Has Everything

At this point in your life, you've probably purchased and received a countless amount of gifts. From Mother's Day to Valentine's Day and all the birthdays, baby showers, and housewarming parties in between, it seems like our world is constantly finding ways to celebrate one another. As much as that is tons of fun, there's also a lot of pressure to show how much you love someone through a physical item—especially when it comes to figuring out a wedding gift idea to get *that* couple in your life who seems to have it all.

What is the best gift for a wedding?

Figuring out how to please a set of two separate humans while celebrating their love and upcoming marriage can be difficult, which is precisely why I called in wedding planner and event manager Chanakya Gandhi, who's seen at least thousands of wedding gifts throughout the years. First things first? "Put yourself in the newlywed couple’s shoes," he says. "Make sure you would actually want the gift you're getting them."

Peep a few of the best wedding gift ideas, below:

Gift Card

Date Night Cookbook and Activities for Couples

Waterproof 4k Digital Camera with Touch Screen

Hand Casting Kit

Push Pin World Map Board

Multi-Photo Frame Wood Tray

Yellow Label Champagne Gift Box

Pre-Seasoned Cast Iron Reversible Grill/Griddle

Engraved items

Contact White Dog Engraving

To learn more about our DFW Engraving services, contact us today by calling (972) 848-7790 or click here.

Unique Engraved Gifts for a Personalized Touch

Searching for unique engraved gift ideas? Click here!

Everyday items such as dog bowls, clocks, or silverware can take on new meaning when you engrave them with something personal, like a monogram or phrase that’s significant to you and the gift’s recipient.

An engraved gift shows that you went the extra mile to make the item more personal, and it can be especially meaningful when given as a wedding or anniversary present.

Regardless of the occasion or the recipient, a wide range of objects can be engraved, which likely makes selecting a gift less challenging. If the options are still overwhelming to you, this guide breaks down top-rated items by price point, so shopping can be less tedious and more fun.

How to Choose the Best Engraved Gifts

Before you begin the adventure of finding the perfect engraved gift, it can be helpful to consider a few questions about the recipient. This way, you can narrow down the selection to the perfect few. Ask yourself:

What hobbies or activities does the person I’m shopping for enjoy? If they’re a frequent entertainer or love to cook, personalized items in those categories will make the most sense.

What everyday items do they need that can be made more personal? From keychains to phone chargers to cutting boards, a custom engraving or monogram can add that special touch to a simple object.

What is your budget? We’ve broken down gift suggestions by price range, so it’s easy to figure out which gifts best suit your predetermined price range.

The Best Engraved Gifts

Peanut Butter Spoon

From elegant serving platters to dog bowls to Christmas ornaments, these engraved gifts add a personal touch that makes each one more memorable.

The next time your best friend or family member picks up a spoon to dig into their morning bowl of cereal or yogurt, this personalized Peanut Butter Spoon can remind them of you or an inside joke you share. Hand-stamped with the phrase or wording of your choice, this standard stainless steel spoon adds meaning to everyday meals or snacks. You can say “Hello Handsome,” or “I love you, Mom,” in a unique way with this spoon, which is available as a teaspoon or tablespoon. The words are stamped into the metal, and the ink used to stamp the lettering is food-safe.

Personalized Key Chain

For a new driver or someone you love, this Personalized Bar Key Chain is a great way to remind them to stay safe on the road or send them off with a sentimental note. Available in silver, gold, or rose gold, the keychain can be engraved on one or both sides with a message, signature, or even a fingerprint to let your gift recipient know you care. Each item is made to order, so it will be unique.

Engraved Ornament

Help new parents celebrate their little one’s first Christmas with the Precious Moments Premium Engraved Ornament. The ornament is a beautiful memento that can be skillfully etched with the year, the name of the baby, and an additional line of text on a bevel-cut glass ornament. An elegant ribbon adds a finishing touch to hang on any style tree, and it comes in a velvet drawstring bag to ensure it stays in pristine condition year after year.

Contact White Dog Engraving

To learn more about our Dallas Texas engraving service, contact us today by calling (972) 848-7790 or click here.

How Does Laser Engraving Work?

Laser etching, laser marking, and laser engraving are all applications that can be satisfied by an industrial laser cutting machine.

Are you thinking about hiring an engraver but you don’t know how laser engraving works?

In this article, we will offer you several tips on how the laser engraving process works.

Understanding Laser Engraving

Laser etching, laser marking, and laser engraving are all applications that can be satisfied by an industrial laser cutting machine. Laser machines vary significantly in their function and properties: there are CO2 laser engraving machines which primarily emit low-powered laser beams and could fit comfortably on your desk, and there are also high-powered fiber lasers that have been purposefully designed to facilitate high-volume laser marking and engraving applications in an industrial setting. Different lasers vary based on the specific chemistry that they use to create the laser beam.

In general, all laser cutting machines have three common components: the laser itself, the control system for the laser, and the marking surface. The operator of the machine uses a software program to modify settings on the laser cutter, including the power output of the laser and the speed of the controller that directs the laser across the material surface.

These settings can be used to change the laser cutter application from laser engraving to laser etching or marking. An image chosen for engraving onto a given material must be produced with graphics editing software.

These include well-known applications such as Adobe Illustrator, Inkscape, and Adobe Photoshop, and AutoCAD that can produce vector files. Vector files have a special property that makes them ideal for the laser marking application: the images in vector files maintain their clarity and proportions when adjusted to any size.

A saved vector file containing the desired image can be uploaded into the laser cutter software and translated into numerical data. The laser cutter’s own software can take that data and use it to program the laser machine’s controller apparatus to produce the provided image using the laser. Conceptually, you might think about laser engraving machines as being similar to 3D printers.

They both use digital designs to automate a creative process, but while a 3D printer functions by printing plastic blocks in the programmed pattern, the laser machine uses a programmed pattern to take something away from the material–leaving engraved text or a lasting image in its place.

Contact White Dog Engraving

At White Dog Engraving, we specialize in engraving services for the Dallas Texas area.

To learn more about our services, contact us today by calling (972) 848-7790 or click here!

Father’s Day 2022 Gift Ideas

Are you searching for Father’s Day gift ideas? If so, you’ve come to the right place!

Fathers-Day is coming up quickly! Thankfully, you can get prepared for Dad’s big day by giving him one of these great gifts.

Gold Electric Toothbrush From Moon

If you think your dad is the king of your family, then he deserves a gift fit for a king, and what would be more kingly than a gold electric toothbrush and toothpaste like this collection from MOON. Combining innovative technology with better-for-you ingredients, the collection includes MOON’s best-selling Electric Toothbrush in a luxe gold colorway and the brand new 24K Gold Gel Toothpaste with a signature Cinnamint flavor. The ergonomic Electric Toothbrush ($69.99 as is or $59.99 with brush head subscription) has 5 sonic cleaning modes for targeted results, premium ultra-fine bristles for optimal reach, and holds an industry-leading 6-week charge. The gentle, fluoride-free 24k Gold Gel Toothpaste ($12.99) polishes and whitens teeth with 24K gold mica flakes that sparkle on your toothbrush.

Nomad x Orbitkey key organizer

If your dad still carries old-school keys on a boring jangly key ring, then he’ll love the Nomad x Orbitkey key organizer. This collaboration between Nomad and Orbitkey elevates Orbitkey’s popular key organizer with a Horween leather strap from Nomad.

Made from vegetable-tanned Horween Leather from the USA and designed with a custom stainless-steel D-ring, this key organizer is designed to carry 2-7 traditional keys in a silent stack for better pocket carry. It has that wonderful new leather smell and looks great.

WESN Father’s Day Gift Boxes

If your dad is into EDC, then you can’t go wrong by getting him a Father’s Day Gift Box from WESN. All boxes are built around one of WESN’s popular knives like the MicroBlade, Allman, Henry, or Samla and also include a bunch of other great gear for keeping the blade sharp. Everything is boxed up and ready to hand to Dad. They are currently selling their Father’s Day gift boxes for 25% off, so it’s a great deal for both you and Dad.

Contact White Dog Engraving

To get your Father’s Day 2022 gifts engraved, contact us today by calling (972) 848-7790 or click here.

Fort Worth Engraving – Contact White Dog Engraving Today!

Are you searching for Forth Worth Engraving? If so, contact White Dog Engraving today by calling us at (972) 848-7790 or connect with us online.

Are you searching for Forth Worth Engraving? If so, contact White Dog Engraving today by calling us at (972) 848-7790 or connect with us online.

We specialize in laser engraving services and can offer you fast service for your engraving needs, especially if you need awards, plaques, badges or glass engraved for your business.

Your Fort Worth Engraving Service

Finding an engraver that you can trust is difficult; thanks to White Dog Engraving, you finally have an engraver that can have confidence in knowing that the job will be done right.

Besides offering excellent service, our company also offers fast turnaround time as well so it doesn’t matter if you need something engraved fast, you can rely on us for all of your DFW engraving needs.

Common Engraving Questions

How much do you charge to engrave something?

There is no set price since all job requests are different. You can request for a quote by contacting us at 972-848-7790.

Do you have discounts for bulk order?

Yes, we do! Our laser service is at a lower rate for larger jobs. Please discuss with your salesman to learn more.

Can I bring my own material instead of using yours?

Absolutely yes! Let us know what material you plan to use and we can advise from there. If we can work with your material, you can ship your material to us or drop them off for your order.

Can you laser engrave cylindrical object such as water bottle?

Yes, we can. We use a rotary device to turn the object while engraving.

What kind of items can you primarily engrave on?

We are able to engrave on a variety of items that include, but not limited to: wood, acrylic, fabric, glass, coated metals, ceramic, deleon, cloth, leather, marble, matte board, melamine, mother of pearl, paper, mylar, pressboard, runner, wood veneer, fiberglass, painted metals, tile, plastic, cork, coriander, anodized aluminum, stainless steel, brass, titanium, bare metals and more.

Contact White Dog Engraving

To learn more about our Fort Worth Engraving service, contact us today by calling (972) 848-7790 or click here to connect with us online.

3 Gorgeous Engraving Techniques You’d Absolutely Love

1. CNC Rotary engraving

CNC Rotary engraving is very similar to the traditional – ancient hand carving technique. This milling machine, with only one difference from the traditional carving, is ideal for highly detailed engravings.

The Rotary machine is designed to produce ideal copies of a piece with its rich details, in well-polished, precise and short-term manner.CNC (computer numerical control) miller has a 3-axis tool, which follows and interprets certain path (lines) pre-drawn in a CAD software by the designer.

G code – is the language which tells the rotary machine to cut through the material or cut (engrave) to a certain depth. It also reads inside the line, outside the line and on the line cutting commands.3 axis

X axes – runs from left to right

Y axes – runs from top to bottom

Z axes – is the zero point and the process

2. CNC Laser engraving

The laser engraving sends laser pulses to make incisions – burns or cuts host of materials.

The laser head runs back and forth to produce clear cut and very detailed engravings.

The materials that work wonders for laser engraving are Acrylic, wood, Lexan, etc.

Depending on the final effect, we can control the direction, speed, depth and the size of the detailed engravings on different surface properties.

This computerized machine must have illustrator files for the laser to cut at a certain thickness and certain lines.

Different laser machines offer variety of depths to personalize and customize the suitable material. For example, dense materials can handle up to 0.020 deep engravings.

3. 3D engraving

At a touch of a button, CNC milling can create 3D signs. The Milling machine can engrave graphics, ornaments to a fine piece of artwork.

3D design process is practiced on materials such as Wood(of course), Acrylic and even metal.

The multi-spindle router creates squiggly, curved lines with a batch of extensive CNC tools which highly resembles manual carving – but done at less time and reduced manpower.

But there’s more than that.

Techniques

3d engraving on the CNC routers is similar to bright-cut engraving with V-point engraving tools. The G-code language (the encrypted dialect of the CNC routers) interprets the vectors and raster images from the results obtained by the software. The V-point can vary to 360 degrees. The tools mimic the cutting and texturing motion of hand tools such as roulets and burnishers (Source: Wikipedia — engraving) by removing the material as the piece rotates on the 360 degrees rotary.

More

Contact White Dog Engraving

For more information about our engraving services, contact us today by calling (972) 848-7790 or click here to connect with us online.

The Best 19th Anniversary Gift Ideas for Your Spouse or the Happy Couple

Looking for a great idea for a 19th wedding anniversary gift? Whether you want something traditional, modern, or unique, we've got you covered with these stylish picks!

Looking for a great idea for a 19th wedding anniversary gift? Whether you want something traditional, modern, or unique, we've got you covered with these stylish picks!

We have included third-party products to help you navigate and enjoy life’s biggest moments. Purchases made through links on this page may earn us a commission.

Celebrating a 19th wedding anniversary is a major marital milestone. You've done nearly two decades together, and it's certainly worth paying homage to all those years of marriage with a great gift. Whether you want to surprise your sweetie with something sentimental or congratulate a special couple in your life, there are anniversary gift ideas galore worthy of celebrating 19 years of wedded bliss. Okay, it's probably been more like 19 years of highs, lows, and everything in between, but whatever the case, gifts are most certainly in order. To help you narrow down your options, we've scoured the internet for a host of awesome ideas, from sweet and sentimental traditional gifts like jewelry to more modern and quirky picks.

What is the traditional 19th anniversary?

The 19th wedding anniversary gift themes are all about bronze. Known for its durability, bronze is a great representation of a marriage that has endured for 19 years. Not only are both the traditional and modern themes bronze, but it's the anniversary's official color too. As for the 19th-anniversary flower, well, there isn't any official one—however, many people tend to go with bronze-colored flowers like the bronze chrysanthemum. And while bronze may be used for third-place medals, there are plenty of great bronze anniversary gifts that will take first place in their hearts.

Want to go beyond the milestone's traditional material? No problem. The 19th wedding anniversary gemstone is the vibrant aquamarine. That being said, no rule says you have to stick with the themes at all. When you've been married for 19 years, almost anything goes, so we've rounded up some great alternative gifts as well.

The Best 19th Anniversary Gifts

As you can see, there's plenty of inspiration to be had when it comes to honoring 19 years of marriage. Here, we've narrowed it down to some of the best traditional, modern, and alternative 19th-anniversary gift ideas to help you say "I love you," "Thanks for sticking with me," or "Congratulations."

1. Sentimental strand

Could there be a more perfect 19th wedding anniversary gift than this "We Are One" necklace? We think not. Not only is made of—you guessed it—bronze, but it features two interlocking rings to "symbolize the strength of love." (Awwh!)

2. Unique whiskey glasses

Raise a glass to the 19th year of marriage with these gorgeous handmade bronze pottery whiskey glasses. Each one holds about seven ounces of their favorite beverage—bonus points if you gift it with a bottle, too. There's also the option of having the tumbler personalized with the number 19 in honor of your milestone.

3. Cool cufflinks

Take inspiration from the 19th-anniversary gemstone with these dapper aquamarine jade cufflinks. Set in sterling silver, they'll add a fancy flair to your spouse's shirtsleeves.

Get Those Gifts Engraved With By White Dog Engraving

At White Dog Engraving, we offer fast and convenient engraving services.

You can count on us to complete your project on time and personalize your gift so that it's the most memorable gift that your spouse will receive from you.

To learn more about our services, contact us today by calling (972) 848-7790 or click here to connect with us online.

Unique Bridesmaid Gift Ideas

Searching for unique bridesmaid gifts for your bridesmaids? If so, click here!

While giving your bridesmaid thank-you gifts isn't required, it never goes unappreciated. "Your bridesmaids are here to provide support throughout the entire wedding planning journey," says Kisha Damali, owner and creative director at D'MALI, a New York City-based design studio that specializes in gifting. "What better way to show how much you value their time and assistance during the most important milestone of your life than with a gift?" she continues. From pitching in for the bridal shower to organizing a bachelorette getaway and volunteering their time for bridesmaid dress fittings, it's safe to say your crew has earned some appreciation.

1. On-Theme Candles

Embrace the celebratory theme by choosing this "Let's Toast" candle with notes of grapefruit, apple, and champagne grapes as a gift for your bridesmaids on your wedding day. You can personalize the back of the glass jar with a sweet, personal note thanking them for being your besties. There's also the option to add Sugarfina champagne-flavored gummy bears or sugar lips for an extra-sweet present.

2. Travel Jewelry Cases

If your girls are always on the go, there are lots of useful bridesmaid gifts to complement their carry-ons. This gorgeous jewelry case is something they'll turn to on the regular. It's not just great for travel—they can safely stow their jewelry in the case all the time. With a luxurious leather finish, it'll look great on their dresser.

3. Sentimental Photo Books

You've shared so many wonderful memories. For the ultimate bridesmaid gift, make a photo book filled with favorite photos of your biggest adventures. Artifact Uprising's online editing tools make creating your memory book a breeze, and you can customize the cover with your preferred image and title. Trust us, this gift will be treasured forever.

4. Surprise Celebrity Greetings

Shopping for someone who already seems to have everything? Experiential gifts are your best bet. Cameo lets you request a personal video message from a celebrity. There are lots of famous faces on the platform, from pro athletes to actors, musicians, and reality stars. Believe us when we say it'll be a bridal party gift to remember. (Psst, Cameo is also a great way to coordinate memorable bridesmaid proposals.)

5. Portrait Champagne Flutes

Personalized bridesmaid gifts are always a good idea. It shows your 'maids that you went the extra mile to pick out something just for them, and if it's anywhere near as awesome as these flutes, it'll come in clutch for years to come. Your crew will never tire of sipping sweet champagne from a glass with their portrait painted on it.

Engrave Those Bridesmaid Gifts At White Dog Engraving

Instead of giving generic bridesmaid gifts, why not engrave them?

At White Dog Engraving, you can personalize those bridesmaid gifts so that your wedding will be something that your girls remember for years to come.

To learn more about our engraving services, contact us today by calling (972) 848-7790 or click here to connect with us online.

A Quick Guide to Laser Engraving

What is Laser Engraving? Laser engraving is a special type of laser marking that produces similar results when compared to traditional engraving methods, but without the use of inks or tool bits that contact the surface material. Laser engraving is best understood in contrast with its sister technologies–laser etching and laser marking. In laser marking, a low-powered laser beam is moved slowly across the target material. The beam slightly discolors the material, creating high-contrast, permanent markings without damaging or compromising the structural integrity of the material. Laser marking is often referred to as laser coloration or laser dark marking, nomenclature which emphasizes the fact that the material is unaffected by the application of the marking. Laser engraving uses a high-powered laser beam to vaporize the surface of the target material, leaving a cavity whose depth can range from one fiftieth to one eighth of an inch. Laser engraving works with a variety of materials, including plastic, wood, anodized aluminum, stainless steel, and glass surfaces. Laser engraving is especially useful for marking parts that are expected to experience high levels of wear throughout their useful life, as the deep penetration of the laser in the engraving process assures the permanence of markings. A third application, laser etching, takes place when a high-powered laser beam is used to melt the surface of the target material, causing it to expand and leaving a visible, raised mark on the material surface. Laser etching can be applied to a variety of surfaces and materials and typically removes less than one thousandth inch of the material surface.

Laser etching, laser marking, and laser engraving are all applications that can be satisfied by an industrial laser cutting machine. Laser machines vary significantly in their function and properties: there are CO2 laser engraving machines which primarily emit low-powered laser beams and could fit comfortably on your desk, and there are also high-powered fiber lasers that have been purposefully designed to facilitate high-volume laser marking and engraving applications in an industrial setting. Different lasers vary based on the specific chemistry that they use to create the laser beam. In general, all laser cutting machines have three common components: the laser itself, the control system for the laser, and the marking surface. The operator of the machine uses a software program to modify settings on the laser cutter, including the power output of the laser and the speed of the controller that directs the laser across the material surface. These settings can be used to change the laser cutter application from laser engraving to laser etching or marking. An image chosen for engraving onto a given material must be produced with graphics editing software. These include well-known applications such as Adobe Illustrator, Inkscape, and Adobe Photoshop, and AutoCAD that can produce vector files. Vector files have a special property that makes them ideal for the laser marking application: the images in vector files maintain their clarity and proportions when adjusted to any size. A saved vector file containing the desired image can be uploaded into the laser cutter software and translated into numerical data. The laser cutter’s own software can take that data and use it to program the laser machine’s controller apparatus to produce the provided image using the laser. Conceptually, you might think about laser engraving machines as being similar to 3D printers. They both use digital designs to automate a creative process, but while a 3D printer functions by printing plastic blocks in the programmed pattern, the laser machine uses a programmed pattern to take something away from the material–leaving engraved text or a lasting image in its place.

Laser Engraving for the Aerospace and Defense Industries Laser marking for aerospace parts represents an exciting new area of application for laser marking and engraving technologies. The aerial vehicles assembled by major contractors in these industries incorporate thousands of parts that travel through a complex global supply chain from their point of origin to the manufactured product, with numerous stops along the way. In order to promote quality and accountability throughout the supply chain, parts-makers in this sector are using laser engraving machines to mark products with barcodes and serial numbers that establishes their traceability. There are significant benefits for manufacturers that choose laser engraving over alternative marking methods for aerospace parts: Low Variable Costs – Chemical etching is a frequent substitute for laser engraving and entails the use of a strong acid to mark the material. Companies that use this method need adequate wastewater treatment or an appropriately certified third-party company to responsibly dispose of chemical waste, and each new image requires a brand new stencil to be produced. In contrast, laser engraving machines have zero inputs besides the power it takes to run them. This translates into low and predictable costs for manufacturers.

Contact White Dog Engraving

Need laser engraving? We can help you with all of your engraving needs!

To learn more about the engraving services we can offer you, contact us today by clicking here.

Metal Engraving Tools Explained: How To Choose And Prepare Gravers For Jewelry Work

Many industries have need of specialized engravers, for instance those who make dies, who cut stones and glass, and others who carve reliefs. Though a goldsmith might call on a specialist for certain jobs, it is useful to have a general understanding of the technique and sufficient skills to use gravers for simple everyday tasks at the bench.

How the Engraving Tool Works

Engraving tools are miniature chisels made of hardened steel. They are chip forming tools and subject to the same forces described in Chapter 5. In proper engraving a sharpened tool is set against the metal at a specific angle and pressure applied both downward and forward. The tool buries itself into the sheet, forms a chip, and pushes that curl of metal ahead of it as it cuts.

The angle of attack is important to achieve a controlled and uniform cut. If the angle is too steep the tool digs itself into the sheet making it impossible to push it forward. The effort to overpower a buried tool can result in a loss of control and a broken tip. If the angle is too shallow the point never gains purchase on the sheet. There is no chip formed and no cut made. Because the tip of the tool is not caught by the metal, the tool easily slips, creating a nasty scratch.

The proper angle will depend on the shape of the graver, the quality of the desired line and the metal being cut. Understanding and responding to these factors requires a sensitive touch and considerable experience.

Engraving Tool Shapes

Engraving tools, called gravers, are precise instruments. They must be made from top quality steel, shaped and sharpened to specific angles, and fitted into handles that provide comfort and control. Commercially available gravers are made from a highly refined fine grained tool steel. A high speed steel is to be recommended for working harder materials and to have the greatest possible durability; there are even engraving tools with carbide cutting tips.

Contact White Dog Engraving

For more engraving tips, or to speak with us about our engraving services, contact us today by clicking here.

Engraving Tips And Tricks

Whether you are an accomplished engineer or a novice maker, learning the proper uses of design equipment to avoid pitfalls and mistakes takes time and experience.

From time to time, issues come up that leave designers wondering what they did wrong or how they could do something better. This is true in any field and laser engraving is no different.

Knowing how to avoid these mistakes so they don’t come up again is half the battle. With that in mind, let's talk about five of the most common mistakes when it comes to laser engraving and ways to avoid them in future projects.

Mistake 1: Engraving Fabric but the Laser Burns through the Material

The first step in avoiding burning fabric with a laser engraving/cutting machine is to understand which fabrics can withstand the process and at what temperatures. Heartier fabrics such as denim, canvas and leather can withstand higher power settings during engraving. But when it comes to delicate fabrics, it is important to start your settings at high speed (near or at 100%) and low power (around 5% to 10%). Test these initial settings on some spare material, and if the fabric can withstand it, increase the power until you get the results you are looking for.

When it comes to direct-to-garment engraving, it is helpful to lower the dots per inch (DPI) at which you engrave. The higher the DPI, the more material will be removed. Engraving at a lower DPI helps ensure the laser just slightly vaporizes the top layer and doesn’t burn entirely through the fabric. Most fabric engravings do fine at 150 to 300 DPI.

5 Common Mistakes in Laser Engraving and How to Avoid Them

Take your engraving to the next level with these helpful tips.

February 2nd, 2018 by Amy Dallman

Whether you are an accomplished engineer or a novice maker, learning the proper uses of design equipment to avoid pitfalls and mistakes takes time and experience.

From time to time, issues come up that leave designers wondering what they did wrong or how they could do something better. This is true in any field and laser engraving is no different.

Knowing how to avoid these mistakes so they don’t come up again is half the battle. With that in mind, let's talk about five of the most common mistakes when it comes to laser engraving and ways to avoid them in future projects.

Mistake 1: Engraving Fabric but the Laser Burns through the Material

The first step in avoiding burning fabric with a laser engraving/cutting machine is to understand which fabrics can withstand the process and at what temperatures. Heartier fabrics such as denim, canvas and leather can withstand higher power settings during engraving. But when it comes to delicate fabrics, it is important to start your settings at high speed (near or at 100%) and low power (around 5% to 10%). Test these initial settings on some spare material, and if the fabric can withstand it, increase the power until you get the results you are looking for.

When it comes to direct-to-garment engraving, it is helpful to lower the dots per inch (DPI) at which you engrave. The higher the DPI, the more material will be removed. Engraving at a lower DPI helps ensure the laser just slightly vaporizes the top layer and doesn’t burn entirely through the fabric. Most fabric engravings do fine at 150 to 300 DPI.

Mistake 2: Acrylic Doesn’t Produce a Frosty White Engraving

More than likely, this is caused by using the wrong acrylic in the application. Two types of acrylics are typically used in laser engraving and both are suitable for different applications.

Cast acrylic sheets and objects are made from a liquid acrylic that is poured into molds that can then be set into various shapes and sizes. This type of acrylic is ideal for engraving because it turns a frosty white color when engraved, making it suitable for awards and plaques. It can be cut with a laser, but it won’t give projects flame-polished edges.

The other type of acrylic used in laser engraving is called extruded acrylic, which is formed into sheets by a machine. Extruded acrylic is generally less expensive than cast acrylic because it is formed through a higher-volume manufacturing technique. However, it does react very differently with the laser engraving machine. This type of acrylic cuts cleanly and smoothly and produces a flame-polished edge; however, when engraved, it doesn’t produce that frosted look, but rather a clear engraving. So make sure you are using cast acrylic if you want a frosted white finish.5 Common Mistakes in Laser Engraving and How to Avoid Them

Take your engraving to the next level with these helpful tips.

February 2nd, 2018 by Amy Dallman

Whether you are an accomplished engineer or a novice maker, learning the proper uses of design equipment to avoid pitfalls and mistakes takes time and experience.

From time to time, issues come up that leave designers wondering what they did wrong or how they could do something better. This is true in any field and laser engraving is no different.

Knowing how to avoid these mistakes so they don’t come up again is half the battle. With that in mind, let's talk about five of the most common mistakes when it comes to laser engraving and ways to avoid them in future projects.

Mistake 1: Engraving Fabric but the Laser Burns through the Material

The first step in avoiding burning fabric with a laser engraving/cutting machine is to understand which fabrics can withstand the process and at what temperatures. Heartier fabrics such as denim, canvas and leather can withstand higher power settings during engraving. But when it comes to delicate fabrics, it is important to start your settings at high speed (near or at 100%) and low power (around 5% to 10%). Test these initial settings on some spare material, and if the fabric can withstand it, increase the power until you get the results you are looking for.

When it comes to direct-to-garment engraving, it is helpful to lower the dots per inch (DPI) at which you engrave. The higher the DPI, the more material will be removed. Engraving at a lower DPI helps ensure the laser just slightly vaporizes the top layer and doesn’t burn entirely through the fabric. Most fabric engravings do fine at 150 to 300 DPI.

Mistake 2: Acrylic Doesn’t Produce a Frosty White Engraving

More than likely, this is caused by using the wrong acrylic in the application. Two types of acrylics are typically used in laser engraving and both are suitable for different applications.

Cast acrylic sheets and objects are made from a liquid acrylic that is poured into molds that can then be set into various shapes and sizes. This type of acrylic is ideal for engraving because it turns a frosty white color when engraved, making it suitable for awards and plaques. It can be cut with a laser, but it won’t give projects flame-polished edges.

The other type of acrylic used in laser engraving is called extruded acrylic, which is formed into sheets by a machine. Extruded acrylic is generally less expensive than cast acrylic because it is formed through a higher-volume manufacturing technique. However, it does react very differently with the laser engraving machine. This type of acrylic cuts cleanly and smoothly and produces a flame-polished edge; however, when engraved, it doesn’t produce that frosted look, but rather a clear engraving. So make sure you are using cast acrylic if you want a frosted white finish.

Mistake 3: Inconsistent Glass Engraving

Oftentimes, when a laser strikes glass it will fracture the surface but not engrave deeply or remove the material needed to engrave fully. The fractured glass surface will produce a frosted appearance, but can be rough and chipped depending on the type of glass that is being engraved. While the frosted look is desired, no one wants a rough surface or chipping.

In order to produce a smooth frosted finish, try incorporating one or several of the tips below:

Use a lower resolution, about 300 DPI, which will produce a better result on glass as you separate the dots you are engraving.

Change the black in your graphic to 80 percent black.

Run your laser engraver with Jarvis Dithering (this dithering pattern can be found in Epilog’s print driver), which will help to provide a smooth finish.

Sometimes, applying a thin, wet sheet of newspaper or a paper towel to the engraving area will help with heat dissipation and improve the engraving process. Just make sure there are no wrinkles in the paper after it is applied.

Another way to dissipate heat is to apply a thin coat of liquid dish soap to the area you're engraving – either with your finger or a paper towel.

Finally, if there are shards of glass after engraving, polish the area with a non-scratch scour pad.

Mistake 4: Wood Engraving Produces Different Results on the Same Setting

Wood is one of the most laser-friendly materials available not only because it can be cut very easily, but also because it engraves very well.

However, different woods have different reactions when they are laser engraved and produce different results. Lighter woods, like cherry or maple, produce a nice contrast where the laser burns away the wood, while denser woods require more laser power to cut or engrave.

Grain density can change dramatically depending on the type of wood you are working with. Cherry, alder, walnut and maple have fairly small veins of grain in them, while oak has medium to large veins. For example, if a large square was engraved into a piece of cherry, it would have a very uniform appearance; the area engraved would be smooth with little variation in height. However, if the same square was engraved into a piece of oak, its appearance would vary greatly in height and would have a very non-uniform appearance.

Here are some tips when engraving with wood:

Maple and alder are some of the the most popular woods for engraving, providing a rich contrast.

Bare wood engraving produces smoke and debris during the process that can become embedded into the grain of the wood. To reduce this effect, always engrave from the bottom up – this helps draw any smoke away from the engraving.

When engraving stained wood, excess smoke and debris can be wiped off the surface of the wood with a damp cloth after engraving.

Contact White Dog Engraving

To learn more about our Dallas Texas engraving service, contact us today by clicking here.

How does laser engraving work?

White Dog Engraving is here to answer any questions you might have for your request. Call or send us an email.

Laser etching, laser marking, and laser engraving are all applications that can be satisfied by an industrial laser cutting machine. Laser machines vary significantly in their function and properties: there are CO2 laser engraving machines which primarily emit low-powered laser beams and could fit comfortably on your desk, and there are also high-powered fiber lasers that have been purposefully designed to facilitate high-volume laser marking and engraving applications in an industrial setting.

Different lasers vary based on the specific chemistry that they use to create the laser beam. In general, all laser cutting machines have three common components: the laser itself, the control system for the laser, and the marking surface. The operator of the machine uses a software program to modify settings on the laser cutter, including the power output of the laser and the speed of the controller that directs the laser across the material surface. These settings can be used to change the laser cutter application from laser engraving to laser etching or marking. An image chosen for engraving onto a given material must be produced with graphics editing software.

These include well-known applications such as Adobe Illustrator, Inkscape, and Adobe Photoshop, and AutoCAD that can produce vector files. Vector files have a special property that makes them ideal for the laser marking application: the images in vector files maintain their clarity and proportions when adjusted to any size. A saved vector file containing the desired image can be uploaded into the laser cutter software and translated into numerical data.

The laser cutter’s own software can take that data and use it to program the laser machine’s controller apparatus to produce the provided image using the laser. Conceptually, you might think about laser engraving machines as being similar to 3D printers. They both use digital designs to automate a creative process, but while a 3D printer functions by printing plastic blocks in the programmed pattern, the laser machine uses a programmed pattern to take something away from the material–leaving engraved text or a lasting image in its place.

Contact White Dog Engraving

For more information about our DFW engraving service, contact us today by calling (972) 848-7790 or click here.

COVID-19 Year 2: A photonics story of growth, shortages, and innovation

Few markets have sustained the steady and healthy growth numbers the photonics market has enjoyed since the 1970s

Few markets have sustained the steady and healthy growth numbers the photonics market has enjoyed since the 1970s. However, when the COVID-19 pandemic hit, it threatened to put an end to the market’s 50-year boom. Fortunately, the photonics market saw far less instability than many anticipated throughout the pandemic. Although the market may not have seen the same growth rates it has enjoyed in previous years, it remained pleasantly stable.

According to recent numbers by Mordor Intelligence, the anticipated growth for the photonics market remains impressive. Specifically, Mordor valued the global photonics market at US$589.82 billion in 2020, and it is expected to reach US$1019.77 billion by 2026. This accounts for an estimated compound annual growth rate (CAGR) of approximately 7.14% during the period of 2021-2026.

Additionally, in June 2021, McKinsey & Co. released its “The Next Wave of Innovation in Photonics” report, which also demonstrated how the track record of dedication to innovation across the photonics markets has enabled the laser-device market to achieve a value of $17 billion by 2020. This same report anticipates a continued growth rate of 10%, yielding market valuation of $28 billion by 2025. Additionally, McKinsey expects to see 8% growth across precision optics sector, as well as 9% growth for photonics sensors. The automotive use of photonic sensors in particular is an area where the firm predicts especially strong growth numbers (21% per annum), attributable to the trend towards autonomy.

The key takeaway from the available numbers? The pandemic remarkably doesn’t seem to have had much effect on the industry, explains Tom Hausken, senior industry advisor with Optica (formerly OSA). “Whereas you hear about downtown office buildings remaining empty and devastating the nearby businesses that serve them, and other lasting impacts from the pandemic, our industry seems surprisingly unscathed,” he says.

“The year 2020 underperformed from what it would have been without the pandemic, and 2021 outperformed as disruptions faded, and pent-up demand drove revenues. Now supply chain issues are restricting growth, but the industry appears to be on track to approximately where it would have been if the pandemic hadn’t happened,” says Hausken. “Looking ahead to 2022, we can expect more of the same. It should be a ‘normal’ year, apart of course from whatever new external disruptions may come our way. But our industry has been strong through two of the most challenging years of our generation.”

One key note: Unlike previous market review articles appearing in Laser Focus World’s January issues, this year’s focus is much broader, looking at the photonics market as a whole rather than narrowing in on the laser subset. The rationale for this shift is significant. Although lasers will continue to serve as a meaningful component of the larger photonics industry, the market has hit a maturity level where it is now important to look at the market in its entirety.

The chip conundrum

It may feel like everyone is “blaming” the chip shortage for current frustrations. After all, it has become a common sticking point across just about every industry today—but for good reason, the number of semiconductor chips in today’s manufactured goods is mind-boggling. Adding fuel to the fire, the need for more chips is intensifying as smart technology becomes the norm (see Fig. 1). Specifically, the persistent drive to leverage artificial intelligence (AI), machine learning, autonomy, and electronification of mobility solutions will only add to the demand expectations.

Simply considering how many chips one product can contain adds context to the issue. For instance, automakers consume roughly 10% of the current chip production with cars containing a range of 100 (internal combustion engine) to as high as 3000 (autonomous battery electric). Smartphones, appliances, Industrial Internet of Things (IIoT) devices, and even toys are all chip hogs rapidly using up the global supply.

According to a December 2021 report by Kearney, “the demand for leading edge semiconductors will increase with an annual growth rate of 15%.” Kearney sites AI, high-performance computing, edge computing, and wireless communications as the key drivers (see Fig. 2), while also estimating these products will account for “more than 80% of leading-edge semiconductor consumption by 2030.”

Contact White Dog Engraving

At White Dog Engraving, we specialize in full service engraving. To learn more about the services that we can offer you contact us today by clicking here.

3 Gorgeous Engraving Techniques You’d Absolutely Love

Engraving is done with a multitude of purposes – to leave a permanent tattoo or some 3D Graphical artworks on Wood, Acrylic, Aluminum, etc. However, given the enormous amount of different engraving solutions – choosing the right one for yourself or your business may become an overwhelming task.

Thus…

To save you time and headache, we put together a brief, comprehensive guide which will help you understand the most popular engraving solutions… and… help you chose the one which will produce the perfect-fit results for you!

Preview

Over the past few decades towards our era, engraving industry experienced robust progress.

Most of today’s engraving methods can be grouped into two main categories: CNC Rotary and Laser engraving. However, one doesn’t work for brittle or soft materials and the other can cause hazardous, life-threatening situations. Thus, these two machines are used interchangeably in a whole host of applications.

1. CNC Rotary engraving

CNC Rotary engraving is very similar to the traditional – ancient hand carving technique. This milling machine, with only one difference from the traditional carving, is ideal for highly detailed engravings.

The Rotary machine is designed to produce ideal copies of a piece with its rich details, in well-polished, precise and short-term manner.CNC (computer numerical control) miller has a 3-axis tool, which follows and interprets certain path (lines) pre-drawn in a CAD software by the designer.

G code – is the language which tells the rotary machine to cut through the material or cut (engrave) to a certain depth. It also reads inside the line, outside the line and on the line cutting commands.3 axis

X axes – runs from left to right

Y axes – runs from top to bottom

Z axes – is the zero point and the process

Techniques

CNC rotary machine is able to make deep cuts into many materials from plastic to Aluminum. Milling routers, are computer-controlled drills, which can engrave shapes and patterns in a variety of models and makes.

• Flat groove engraving

Flat groove engraving is a routing technique, which by removing the material leaves a flat area at the bottom of the sign face.

The depth of the cut can be tailored to individual needs.

The biggest advantage of the Flat groove engravings is that the sign can be painted quickly and easily.

Cast Acrylic Flat groove engraving comes with white matte finish.

• V- groove engraving

This technique is widely used throughout the sign making industry mainly to create Door name plaques, tabletop signs, decorative items, etc.

Unlike Flat groove engraving, V groove comes with a fine line with a bottom tip – ideal both for graphics and lettering. The end-result engraved text can be painted or gold leafed.

V groove works wonders on materials like wood, plywood, MDF and other composites, plastics, etc.

V groove engraving process on a wood. | pay attention to the V groove bit. ⬇

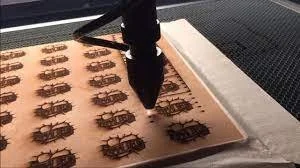

2. CNC Laser engraving

The laser engraving sends laser pulses to make incisions – burns or cuts host of materials.

The laser head runs back and forth to produce clear cut and very detailed engravings.

The materials that work wonders for laser engraving are Acrylic, wood, Lexan, etc.

Depending on the final effect, we can control the direction, speed, depth and the size of the detailed engravings on different surface properties.

This computerized machine must have illustrator files for the laser to cut at a certain thickness and certain lines.

Different laser machines offer variety of depths to personalize and customize the suitable material. For example, dense materials can handle up to 0.020 deep engravings.

Techniques

The laser beam removes selected areas of the subject material creating a desired effect or mark. There are two types of this marking.

As engraving is the common term for both, there is a slight difference between etching and marking.

• Laser Marking

Laser marking is an umbrella term – it includes a whole bunch of laser applications. Marking creates discoloration and pattern (usually of a darker shade than the actual material) into the surface altering both appearance and the properties of the material.

Again, no inks are used – laser marking is permanent and eco-friendly.

Materials such as Wood, leather are ideal for marking – the desired effect depends just on the intensity of the laser beam.

ACM 2018 welcome hammers with laser engravings

• Laser Etching

Etching, a subset of laser marking, is somewhere between laser marking and engraving.

Laser Etching distorts the material a permanent message leaving the surface raised above the rest. Unlike engraving,which can cut as deep as 0.125”, it only has 0.001” depth.

Laser wood etching process of the Coca-Cola logo⬇

3. 3D engraving

At a touch of a button, CNC milling can create 3D signs. The Milling machine can engrave graphics, ornaments to a fine piece of artwork.

3D design process is practiced on materials such as Wood(of course), Acrylic and even metal.

The multi-spindle router creates squiggly, curved lines with a batch of extensive CNC tools which highly resembles manual carving – but done at less time and reduced manpower.

But there’s more than that.

Techniques

3d engraving on the CNC routers is similar to bright-cut engraving with V-point engraving tools. The G-code language (the encrypted dialect of the CNC routers) interprets the vectors and raster images from the results obtained by the software. The V-point can vary to 360 degrees. The tools mimic the cutting and texturing motion of hand tools such as roulets and burnishers (Source: Wikipedia — engraving) by removing the material as the piece rotates on the 360 degrees rotary.

Contact White Dog Engraving

For more information about the engraving services that we can offer you, contact us today by calling (972) 848-7790 or click here!

What is laser engraving?

Interested in learning more about laser engraving? If so, click here!

Laser engraving is a special type of laser marking that produces similar results when compared to traditional engraving methods, but without the use of inks or tool bits that contact the surface material. Laser engraving is best understood in contrast with its sister technologies–laser etching and laser marking. In laser marking, a low-powered laser beam is moved slowly across the target material.

The beam slightly discolors the material, creating high-contrast, permanent markings without damaging or compromising the structural integrity of the material. Laser marking is often referred to as laser coloration or laser dark marking, nomenclature which emphasizes the fact that the material is unaffected by the application of the marking.

Laser engraving uses a high-powered laser beam to vaporize the surface of the target material, leaving a cavity whose depth can range from one fiftieth to one eighth of an inch. Laser engraving works with a variety of materials, including plastic, wood, anodized aluminum, stainless steel, and glass surfaces. Laser engraving is especially useful for marking parts that are expected to experience high levels of wear throughout their useful life, as the deep penetration of the laser in the engraving process assures the permanence of markings.

A third application, laser etching, takes place when a high-powered laser beam is used to melt the surface of the target material, causing it to expand and leaving a visible, raised mark on the material surface. Laser etching can be applied to a variety of surfaces and materials and typically removes less than one thousandth inch of the material surface.

Contact White Dog Engraving

For more information about engraving, or to speak with us about your engraving project, contact us today by clicking here.

What are 3 types of engraving?

Etching. Etching is a process used to cut lettering, logos and graphics into glass, crystal and stone. ...

Inside Ring Engraving. Inside/Outside Ring Engraving allows for that special message of the special event to be with you always. ...

Laser Engraving. ...

Rotary Engraving.

Contact White Dog Engraving

For questions about our Dallas Texas engraving service, contact us today by calling (972) 848-7790 or click here to connect with us online.