What’s New In Laser Engraving?

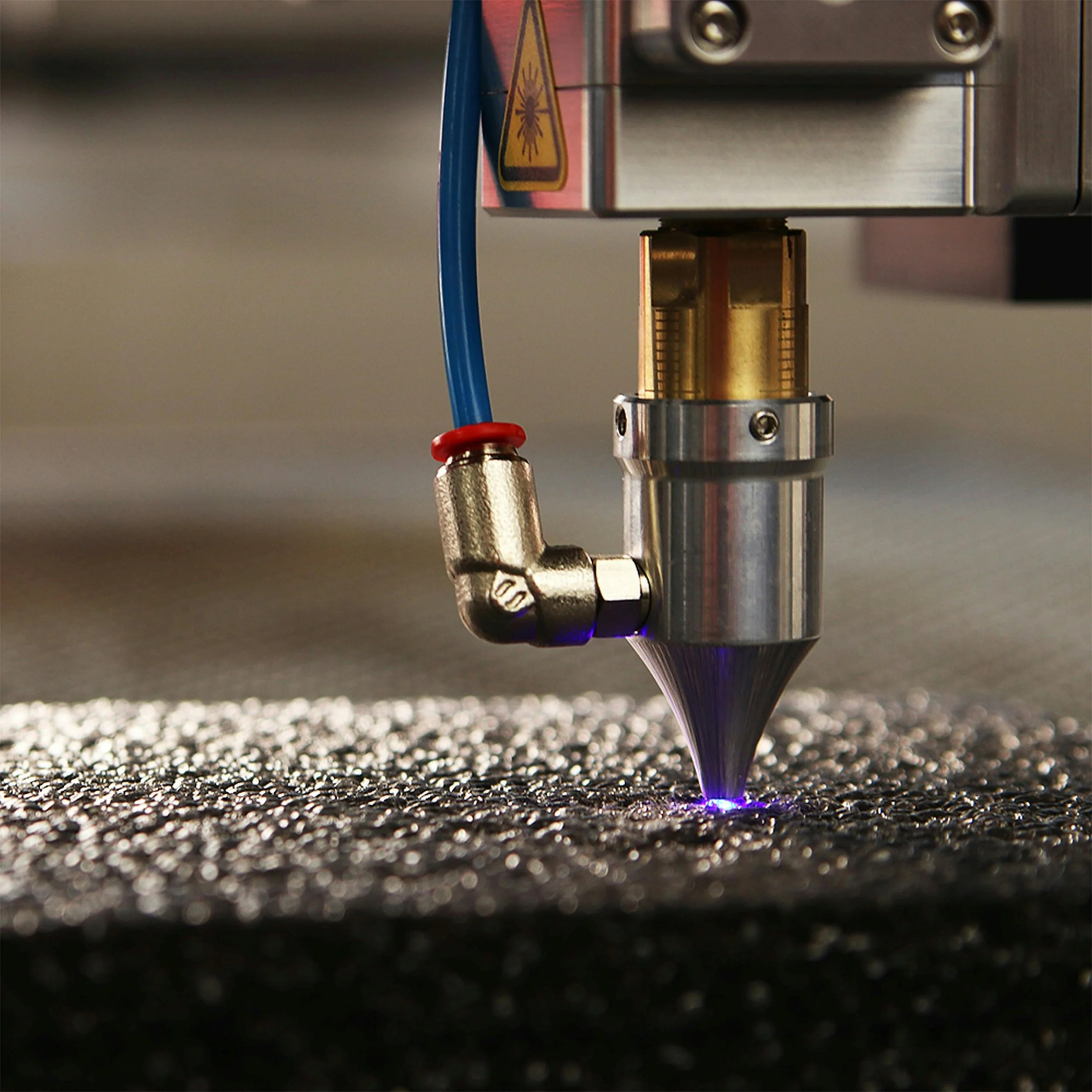

Traditionally, CO₂ lasers dominated large-scale engraving, especially for non-metals.

Traditionally, CO₂ lasers dominated large-scale engraving, especially for non-metals. Now, fiber lasers efficiently engrave metal, plastics, and some White Dog composites. They are becoming more affordable, popular, and capable. A finer beam diameter and lower heat-affected zone allow fiber lasers to achieve sharper details and cause less thermal damage.

Here are more new advancements in laser engraving.

Smarter Automation & AI Integration

Engraving machines are getting smarter. Artificial intelligence and machine learning now dynamically adjust parameters like speed, power, and focus for each material, or in response to variations in the material being engraved. Real-time monitoring, predictive maintenance, and IoT-enabled systems minimize waste and downtime.

Material Innovation & New Substrates

As demand rises for personalization and diverse applications, more professionals are engraving unconventional materials—smart materials, biodegradable or recycled substrates, ceramics, leather, and fabric are all being pushed further than before. Many machines now engrave curved or irregular surfaces.

Improved Hardware & Workflow Enhancements

Better cooling, finer optics, auto-focus, and flexible work areas enable faster engraving, less setup, and consistent quality. Improved material handling speeds up production in industrial settings.

Sustainability & Efficiency

Energy-efficient lasers and eco-friendly materials reduce costs and environmental impact. Businesses can now achieve high performance and sustainability.

Why It Matters

Advancements mean sharper, faster engraving, more material options, and greener operations. Shops and creatives can deliver complex designs, faster production, and improved margins.

Contact Us

If you’re looking for an engraving partner who’s keeping pace with these cutting-edge innovations, White Dog Engraving in Dallas, Texas is ready to bring your ideas to life. Whether you want crisp detail on metal, beautiful personalized designs on wood or leather, or fast turnaround on custom projects—our team uses the latest laser technologies to deliver top quality. Get in touch with us today, tell us what you need, and let White Dog Engraving show you what modern laser engraving can do for your business or project.

Dallas, Texas Engraving Company: Craftsmanship that Leaves a Lasting Impression

Personalized gifts, custom signage, and branded business products become unforgettable with expert engraving. For residents and businesses across North Texas, a Dallas, Texas engraving company offers the skill, technology, and precision needed to turn ordinary materials into memorable, one-of-a-kind pieces. Whether it’s a keepsake for a loved one or a professional branding project, engraving brings timeless beauty and lasting value to nearly any surface.

Personalized gifts, custom signage, and branded business products become unforgettable with expert engraving. For residents and businesses across North Texas, a Dallas, Texas engraving company offers the skill, technology, and precision needed to turn ordinary materials into memorable, one-of-a-kind pieces. Whether it’s a keepsake for a loved one or a professional branding project, engraving brings timeless beauty and lasting value to nearly any surface.

The Art and Science of Engraving

Engraving combines traditional artistry with modern innovation. Skilled technicians utilize tools such as laser engravers, rotary machines, and diamond-tipped instruments to etch intricate designs into various materials, including metal, glass, wood, leather, and more. The process removes a fine layer of material to create permanent markings—such as names, logos, dates, or intricate graphics—that won’t fade or wear away over time.

In Dallas, engraving companies often work with both individual clients and corporate customers. This flexibility enables them to produce a wide range of items, from elegant wedding gifts and trophies to commercial nameplates, industrial tags, and branded promotional products. The versatility of engraving makes it a top choice for anyone who values craftsmanship and precision.

Services Offered by Dallas Engraving Experts

A leading engraving company in Dallas, Texas, typically offers a wide range of services, including:

Laser Engraving: Ideal for intricate designs on materials such as stainless steel, acrylic, glass, or anodized aluminum. Laser engraving ensures precision and consistency for large batches or intricate patterns.

Custom Awards & Trophies: Dallas White Dog engravers often create personalized awards, plaques, and recognition pieces for events, schools, and sports teams.

Industrial Marking: Engraved labels, serial plates, and tags help businesses meet compliance and maintain a professional image.

Gifts and Keepsakes: Engraving makes jewelry, watches, cutting boards, and photo frames into lasting mementos.

Signage & Branding: Businesses use engraved signs and nameplates to convey professionalism and durability in offices or storefronts.

Each project receives precise attention, reflecting the client’s vision and the company’s commitment to quality.

Why Choose a Dallas Engraving Company?

Dallas is renowned for its quality craftsmanship and service, including expert engraving. Local companies blend experience with technology, offering fast turnarounds and precision. Whether you need a single gift or mass production, these experts deliver efficiently and artistically.

A local Dallas engraver offers personal consultation. Clients can view samples, discuss designs in person, and approve proofs before production. This ensures the final piece meets or exceeds expectations.

A Lasting Mark of Quality

In a world of mass production, engraving offers true personalization. A Dallas engraving company delivers craftsmanship that tells a story. Each piece showcases care, attention to detail, and artistry that is remembered for years.

Whether celebrating a milestone, enhancing your brand, or commemorating an occasion, the right Dallas engraver makes it unforgettable—one precise mark at a time.

Get an engraving quote for your business by calling us at (972)848-7790 or click here to connect with us online.

How Long Will My Engraving Project Take?

When planning an engraving project, one of the most common questions is: how long will it take? The answer depends on several key factors, including the material, design complexity, equipment used, and project volume.

The time required for an engraving project depends on the material, design complexity, equipment, and quantity.

1. Material Type

Softer materials, such as wood, acrylic, or leather, engrave quickly. Harder surfaces, such as glass, stone, or metal, require more time, especially when precision is needed.

2. Design Complexity

Simple text engraves in minutes. Detailed logos or fine artwork require more time, as machines must work more slowly to achieve precision.

3. Project Size and Quantity

A single small item may take under an hour. Bulk orders or large quantities may take longer, such as a day or more, for 100 items.

4. Equipment and Expertise

Modern lasers engrave faster. Experienced professionals optimize settings to minimize time and maintain quality.

Typical Turnaround Expectations

Small, simple jobs: same-day or within 24 hours

Moderate projects: 2–5 business days

Large, custom, or bulk orders: 1–2 weeks

Overall, project duration ranges from minutes to weeks, depending on material, design, and quantity. For an accurate estimate, provide your engraver with these details upfront.

Learn more about the engraving projects that we can offer you by calling us at (972)848-7790 or click here.

Laser Engraving Leather Debossing Stamps with MDF and Acrylic

Creating professional debossed designs is easier than ever with a laser engraver in Dallas, Texas. With MDF (medium-density fiberboard) or acrylic, you can create custom leather debossing stamps for crisp impressions on wallets, belts, and other items.

Creating professional debossed designs is easier than ever with a laser engraver in Dallas, Texas. With MDF (medium-density fiberboard) or acrylic, you can create custom leather debossing stamps for crisp impressions on wallets, belts, and other items.

Why Use MDF and Acrylic for Stamps?

MDF is a cost-effective material that works well for engraving intricate details. Its density allows for clean etching, making it a solid choice for hobbyists and small businesses experimenting with stamp creation. Acrylic, on the other hand, is durable and can withstand repeated use without losing White Dog detail. Many crafters prefer acrylic when producing higher-quality stamps designed for long-term use.

The Laser Engraving Process

A Dallas, Texas laser engraver can precisely cut and etch both MDF and acrylic into your desired stamp shape. The process typically involves:

Designing the Artwork – Use vector software to create your logo, text, or pattern. Bold, simple designs tend to stamp better into leather.

Selecting the Material – Choose MDF for affordability and practice runs, or acrylic for durability and sharper details.

Engraving and Cutting – The laser engraver etches the negative space of your design into the material, leaving a raised surface for debossing.

Stamp Mounting – Once engraved, the stamp can be mounted on a wooden block or metal press plate for ease of use.

Using Stamps on Leather

To create the debossed impression, leather should be slightly moistened before pressing. A heat press or hand-operated press applies steady pressure, allowing the engraved MDF or acrylic stamp to leave a permanent, professional-looking mark.

Benefits of Laser-Engraved Leather Stamps

Customization: Ideal for small businesses seeking to brand their products with logos.

Precision: Laser engraving ensures fine details are captured, even on small designs.

Cost-Effective: MDF and acrylic are more affordable than metal stamps.

Local Support: Working with a Dallas, Texas laser engraver provides easy access to custom services, quick turnaround times, and professional expertise.

Contact Us

Whether you’re experimenting with DIY leather projects or running a leather goods business, using MDF and acrylic to make debossing stamps is a smart way to achieve professional results. With the precision of a Dallas Texas laser engraver, you can create long-lasting, detailed stamps that elevate your craftsmanship.

Let’s talk about your engraving project! Contact us today by calling (972)848-7790 or click here to connect with us online.

How To Choose a Laser Cutter, Engraver, or Marker

Laser technology is vital for businesses and hobbyists. Selecting the right laser cutter, engraver, or marker ensures quality results. Consider these key factors when deciding.

Laser technology is vital for businesses and hobbyists. Selecting the right laser cutter, engraver, or marker ensures quality results. Consider these key factors when deciding.

1. Define Your Purpose

Start by identifying what you want to accomplish. A laser cutter is ideal for cutting through materials such as wood, acrylic, and fabric. A laser engraver creates detailed surface designs, while a laser marker is ideal for permanent, high-contrast markings on metals and plastics. Understanding your primary application will significantly narrow your options.

2. Consider Material Compatibility

Different lasers are more effective on specific materials. For example, CO₂ lasers excel with wood, glass, and acrylic, while fiber lasers are better suited for metals. If you need versatility, look for a system that supports multiple material types.

3. Evaluate Power and Speed

The wattage of a laser directly impacts cutting depth and speed. Higher-wattage machines handle thicker materials more efficiently, while lower-wattage models are better for fine engraving work. Balance power with precision depending on your needs.

4. Software and Ease of Use

User-friendly software is critical, especially if you’re new to laser technology. Look for systems with intuitive controls, design compatibility, and strong support communities.

5. Budget and Support

Prices vary widely depending on features and size. Beyond the initial cost, consider factors such as maintenance, replacement parts, and the availability of customer support. A reputable supplier with strong after-sales service can save you time and money long term.

By carefully assessing your goals, materials, and budget, you’ll be well-prepared to select the right laser system—ensuring efficiency, precision, and growth in your projects or business.

Learn more about the engraving services thatwe can offer you by calling us at (972)848-7790 or click here to connect with us online.

Tips for Laser Cutting Plastic: A Guide for Best Results

Laser cutting is one of the most precise and efficient methods for shaping plastics, whether for signage, product prototypes, or custom designs. However, working with plastic requires careful preparation to ensure clean, safe, and professional results. If you’re considering a project that involves engraving or fabrication in Dallas, Texas, here are some key tips for laser cutting plastic.

Laser cutting is one of the most precise and efficient methods for shaping plastics, whether for signage, product prototypes, or custom designs. However, working with plastic requires careful preparation to ensure clean, safe, and professional results. If you’re considering a project that involves engraving or fabrication in Dallas, Texas, here are some key tips for laser cutting plastic.

1. Choose the Right Plastic Type

Not all plastics are created equal. Acrylic is the most common material for laser cutting because it produces smooth, polished edges and handles engraving well. Polycarbonate, on the other hand, should be avoided as it discolors and emits harmful fumes. Always confirm the material’s compatibility with laser equipment before cutting.

2. Adjust Laser Settings Properly

Power, speed, and frequency are critical White Dog settings that determine the quality of your cut. Too much power can melt edges, while too little may leave incomplete cuts. It’s best to run test samples to fine-tune settings for your specific type of plastic.

3. Minimize Heat Build-Up

Plastics are sensitive to heat, which can cause warping or burning. Using air assist during cutting helps blow away heat and debris, keeping edges clean and preventing damage.

4. Keep Safety in Mind

Laser cutting produces fumes when working with plastics. Proper ventilation or a fume extraction system is essential for a safe workspace.

5. Work with Professionals

For intricate designs or large projects, partnering with an experienced shop that offers laser cutting and engraving services in Dallas, Texas, ensures your work is accurate, polished, and handled safely.

By following these tips, you’ll achieve sharp, clean cuts while protecting both your project and your equipment. Laser cutting plastic can be an excellent choice when done with the right materials and settings.

Get a laser engraving quote by calling us at (972)848-7790 or click here to connect with us online.

Top Ideas for Wine Bottle Engraving at Oktoberfest

Oktoberfest is often celebrated with beer steins, pretzels, and festive music, but wine has also become an increasingly popular feature of the season. Personalized wine bottles offer a unique way to commemorate the event, and engraving adds an elegant, lasting touch.

Oktoberfest is often celebrated with beer steins, pretzels, and festive music, but wine has also become an increasingly popular feature of the season. Personalized wine bottles offer a unique way to commemorate the event, and engraving adds an elegant, lasting touch. Whether you are a business seeking promotional opportunities or an individual looking for a memorable keepsake, engraved wine bottles at Oktoberfest make a lasting impression. Here are some top ideas for wine bottle engraving during the festivities.

1. Event Logos and Dates

Engraving the official Oktoberfest logo or the year of the celebration on a wine bottle transforms it into a collectible. This approach is especially appealing for guests who want a souvenir to mark their visit. Businesses can also customize bottles with local festival logos to connect their brand with the festive spirit.

2. Traditional Bavarian Motifs

Images such as pretzels, beer mugs, alpine hats, or edelweiss flowers engraved on wine bottles add a cultural touch. These motifs bring the Bavarian heritage to life and can be paired with text for a fully customized design. Using symbolic elements of the festival enhances the celebratory feel of the bottles.

3. Personalized Names and Messages

For private gatherings or corporate events during Oktoberfest, adding engraved names or short messages makes the bottles stand out. A phrase like “Prost, Anna!” or “Cheers from Munich 2025” turns a standard bottle of wine into a memorable gift. This type of personalization is well-suited for hosts who want to give their guests meaningful mementos.

4. Corporate Branding

Many companies use Oktoberfest as a networking opportunity. Custom-engraved wine bottles with a company logo and tagline serve as premium promotional gifts. They not only highlight the brand but also align it with the festive and convivial atmosphere of Oktoberfest.

5. Commemorative Artwork

Limited-edition artwork can be engraved onto wine White Dog bottles to create collector’s items. Local landmarks, festival tents, or Oktoberfest-inspired illustrations work particularly well. These engraved designs appeal to both tourists and locals who value tradition and artistry.

Conclusion

Engraved wine bottles bring elegance and individuality to Oktoberfest celebrations. From logos and Bavarian motifs to personalized messages and artwork, the options are versatile and memorable. Whether used for personal keepsakes or corporate gifts, custom engraving ensures that each bottle serves as a lasting reminder of the season’s festivities. Take the next step and create your own unforgettable Oktoberfest keepsake or branded gift today.

Recommendation: When promoting engraved wine bottles, emphasize the celebration of Bavarian culture, the possibilities for personalization, and the branding opportunities that this presents. Encourage customers to design or order their engraved bottles now to stand out during Oktoberfest.

Next step: Begin developing engraving templates that blend Oktoberfest symbols with space for custom text. Invite interested customers to reach out or collaborate on custom designs to make their bottles truly unique and memorable.

Get an engraving quote today by calling us at (972) 848-7790 or click here to connect with us online.

5W vs 10W ComMarker Omni 1 UV Laser: Which One Is Right for You?

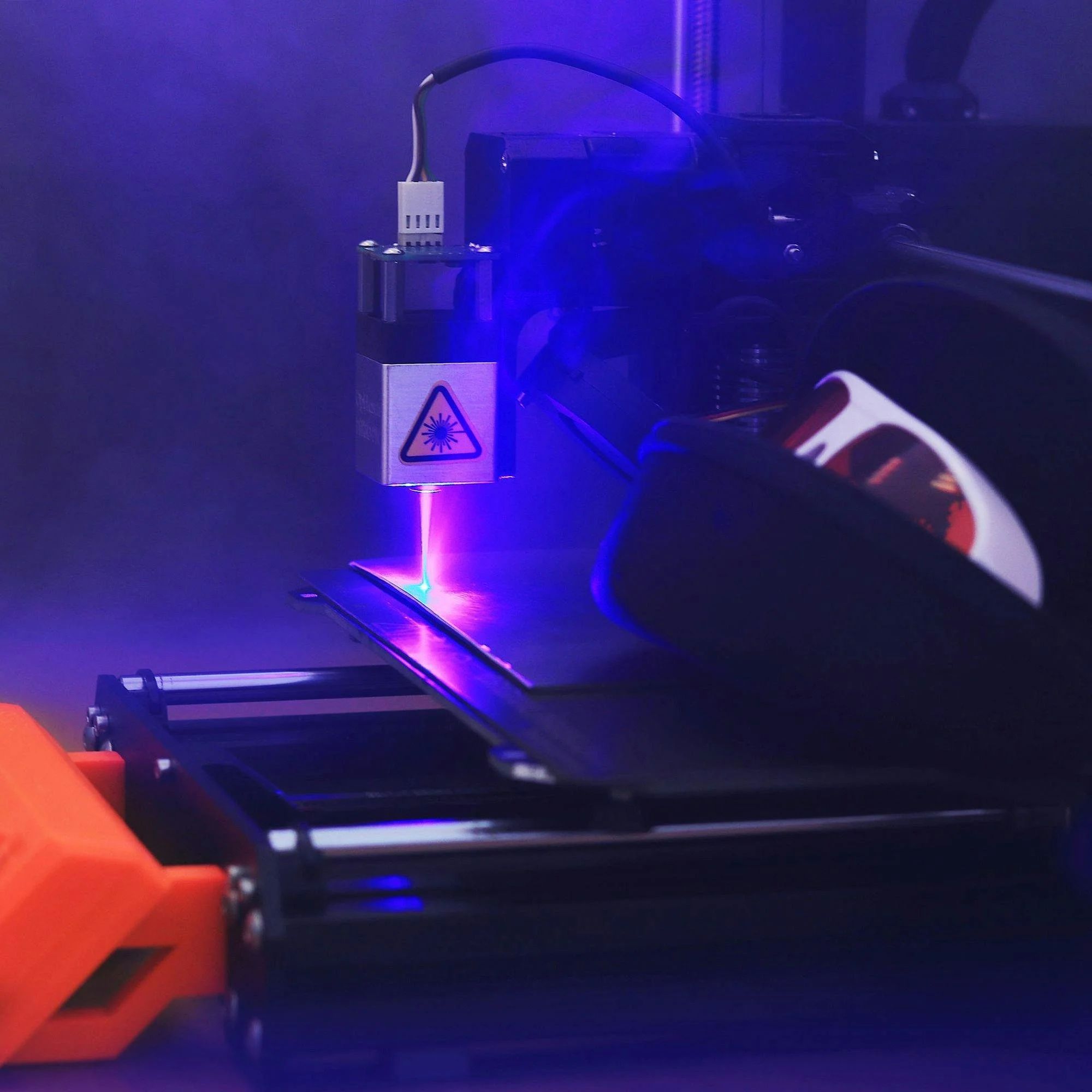

When it comes to laser engraving, precision and efficiency matter. The ComMarker Omni 1 UV Laser series is renowned for its ability to engrave a wide range of materials, including plastics, glass, metals, and even delicate substrates. But if you’re considering investing in this technology, one key decision is whether the 5W or 10W version is the better choice.

When it comes to laser engraving, precision and efficiency matter. The ComMarker Omni 1 UV Laser series is renowned for its ability to engrave a wide range of materials, including plastics, glass, metals, and even delicate substrates. But if you’re considering investing in this technology, one key decision is whether the 5W or 10W version is the better choice.

The 5W ComMarker Omni 1 UV Laser

The 5W model is an excellent entry-level option for businesses and hobbyists who require detailed, high-contrast marking without excessive power consumption. Its lower wattage means less heat, making it ideal for materials that are sensitive to burning, such as plastics or coated surfaces. If your projects involve intricate logos, barcodes, or fine text, the 5W unit provides clean and crisp results with minimal risk of surface damage.

The 10W ComMarker Omni 1 UV Laser

The 10W version delivers more power, resulting in faster engraving speeds and deeper marks. It’s a better fit for high-volume production environments where time is of the essence. The extra wattage also allows for engraving tougher materials, such as certain metals or thicker plastics, with greater efficiency. However, with the increased power comes a higher price point, which may not be practical for smaller-scale operations.

Which One Is Right for You?

The choice between the 5W and 10W ComMarker Omni 1 UV Laser depends largely on your application and budget. If you require precise measurements, the 5W is sufficient. If you’re focused on speed, durability, and handling larger production runs, the 10W is the smarter investment.

But here’s the reality—purchasing and maintaining either machine requires a significant upfront cost and ongoing technical know-how. For many businesses, especially small to mid-sized companies, outsourcing laser engraving to a local engraving company like White Dog Engraving is the more cost-effective option.

Save Time and Money with Local Expertise

Instead of spending thousands on equipment and training, you can achieve the same high-quality results by working with professionals who already have the latest UV laser technology. We can handle your custom jobs quickly, eliminate the learning curve, and save you the headache of equipment maintenance.

If you want precision, speed, and cost savings without the investment, contact us today! You’ll start benefiting from 5W or 10W laser engraving without the expense, saving both time and money while gaining expert results.

Get an engraving quote today by calling us at (972) 848-7790 or click here to connect with us online.

Why Businesses Should Use Laser Engraving to Customize Thermos Bottles

3D laser engraving is an advanced engraving technique that creates depth, dimension, and texture in a variety of materials, resulting in visually striking, tactile designs. Unlike traditional 2D laser engraving, which etches flat designs onto a surface, 3D laser engraving manipulates the surface at multiple depths to produce a layered or sculpted effect.

In today’s competitive market, businesses are continually seeking innovative ways to differentiate themselves, enhance brand recognition, and foster lasting customer loyalty. One increasingly popular strategy is to customize practical products—like thermos bottles—with a company logo or message. Among customization methods, laser engraving has emerged as the top choice due to its superior quality and long-term impact.

Professional, High-Quality Appearance

Laser engraving creates a sharp, precise design that instantly communicates professionalism. Unlike printed or painted logos that can fade, scratch, or peel over time, laser-engraved markings are etched directly into the surface of the thermos. This results in a sleek, permanent finish that retains its clarity and detail even after years of use.

Durability That Matches the Product

Thermos bottles are built for durability—often made from stainless steel or other long-lasting materials. Laser engraving complements that strength, ensuring the customization lasts as long as the bottle itself. Because the engraving is embedded into the material, it won’t wear off from washing, heat exposure, or outdoor conditions. This longevity ensures your branding remains visible through countless uses, making it a cost-effective marketing investment.

Eco-Friendly and Chemical-Free Process

Laser engraving is a clean, eco-friendly customization method. It doesn’t rely on inks, solvents, or chemical treatments, which means there’s no risk of harmful substances leaching into drinks. This is especially important for businesses promoting sustainability or targeting environmentally conscious consumers. By pairing reusable thermos bottles with a chemical-free marking method, companies reinforce their commitment to green initiatives.

Versatile Design Possibilities

From logos and taglines to intricate patterns and personalized names, laser engraving offers incredible design flexibility. The precision of modern laser machines enables the replication of small text, fine lines, and detailed graphics with flawless accuracy. Businesses can even offer personalized bottles for clients, employees, or promotional giveaways, adding a unique touch that strengthens relationships.

Boosting Brand Visibility and Loyalty

A customized thermos bottle is more than just drinkware—it’s a mobile billboard. Whether on a commute, at the gym, or on a camping trip, these bottles showcase your brand to potential customers in a natural, non-intrusive way. Recipients often use them daily, associating your brand with convenience, quality, and reliability.

Contact Us

For businesses seeking a practical, durable, and eco-friendly way to promote their brand, laser-engraved thermos bottles are an excellent choice. They combine long-lasting quality with daily usability, ensuring your message travels wherever your customers go—one sip at a time.

Learn more about our engraving services by contacting us at (972)848-7790 or click here to connect with us online.

What is 3D Laser Engraving and How Does It Work?

3D laser engraving is an advanced engraving technique that creates depth, dimension, and texture in a variety of materials, resulting in visually striking, tactile designs. Unlike traditional 2D laser engraving, which etches flat designs onto a surface, 3D laser engraving manipulates the surface at multiple depths to produce a layered or sculpted effect.

3D laser engraving is an advanced engraving technique that creates depth, dimension, and texture in a variety of materials, resulting in visually striking, tactile designs. Unlike traditional 2D laser engraving, which etches flat designs onto a surface, 3D laser engraving manipulates the surface at multiple depths to produce a layered or sculpted effect.

At its core, 3D laser engraving utilizes a high-powered laser to burn, melt, or vaporize material according to a digital 3D design. The process starts with specialized 3D modeling software, where the desired design is created or imported. This file includes depth data, which instructs the laser on how deeply to engrave at various points on the material. The file is then sent to a laser engraving machine equipped with a dynamic focusing system. This system automatically adjusts the laser’s focus in real time, allowing it to accurately carve varying depths into the substrate.

Understanding Laser Engraving

The laser beam itself is controlled by precise galvanometer mirrors or CNC (Computer Numerical Control) systems, which guide the beam along the X, Y, and Z axes. These controls enable the machine to adjust the laser’s intensity and duration on the material’s surface, producing gradients and intricate curves that are characteristic of true 3D engraving.

Materials commonly used in 3D laser White Dog engraving include wood, acrylic, glass, crystal, metal, and even stone. The applications are widespread, ranging from personalized gifts and trophies to industrial mold-making, architectural models, and artistic sculptures.

One of the standout benefits of 3D laser engraving is the ability to produce incredibly detailed and durable designs without physical contact. This makes it ideal for fragile materials or complex patterns that would be difficult to achieve through manual carving.

Contact Us

In summary, 3D laser engraving is a cutting-edge technique that combines precision technology with digital artistry to transform flat surfaces into dimensional works of art. Whether for commercial, industrial, or creative use, it opens up a world of possibilities in custom design and production.

To learn more about deep laser engraving, or to get an engraving quote for your project, contact us today by calling (972)848-7790 or click here to connect with us online.

Understanding Deep Laser Engraving: What It Is and How It Works

Deep laser engraving is a high-precision process that utilizes a powerful laser beam to etch deep, permanent marks into the surface of a material. Unlike surface engraving, which only removes a small layer, deep laser engraving penetrates several millimeters into the material. This method is ideal for creating long-lasting, high-contrast markings on metal, stone, and other hard materials.

Deep laser engraving is a high-precision process that utilizes a powerful laser beam to etch deep, permanent marks into the surface of a material. Unlike surface engraving, which only removes a small layer, deep laser engraving penetrates several millimeters into the material. This method is ideal for creating long-lasting, high-contrast markings on metal, stone, and other hard materials.

In Dallas, Texas, laser engraving has become a popular solution for industries that require durable identification, such as aerospace, automotive, and industrial manufacturing. Whether it's serial numbers, logos, or custom artwork, deep laser engraving ensures the design remains legible even under harsh conditions, such as extreme heat, friction, or chemical exposure.

How Deep Laser Engraving Works

In this process, a computer controls a laser that shines on the material. The laser’s strength, speed, and the number of times it passes over determine how deeply it engraves. The laser heats and removes material in layers, gradually creating a deeper mark.

Most deep laser engraving uses a fiber laser, which can focus a significant amount of power into a small spot. The laser never touches the material, resulting in clean and even lines, and there is no need to clamp the material.

Benefits of Deep Laser Engraving

One of the main advantages is its permanence. Deep White Dog engravings do not wear off over time, making them ideal for components that undergo frequent handling or exposure to the elements. The precision of laser technology also allows for intricate and complex designs, adding both functionality and aesthetic appeal.

To ensure your marks stand the test of time, reach out to Dallas, Texas laser engraving professionals today and discover how advanced deep engraving services can meet your industrial or personal needs. Contact us now to get started with a durable, high-quality marking solution.

Learn more about our DFW engraving services by calling us at (972) 848=7790 or click here to connect with us online.

Understanding the Difference Between Laser Cutters and Laser Engravers

Laser technology has become an essential tool in many industries, from manufacturing to design. Two of the most commonly used laser machines are laser cutters and laser engravers. While these devices may appear similar and often share components, they serve distinct purposes and operate differently based on the desired outcome.

Laser technology is essential across various industries, including manufacturing and design. Two key machines—laser cutters and laser engravers—look similar but serve different purposes.

Laser Cutters: Precision Slicing

A laser cutter slices materials with precision using a high-powered laser beam focused on a small point. It heats and vaporizes the material for clean cuts. Laser cutters work on a variety of materials, including wood, acrylic, plastic, fabric, paper, and some metals, depending on the power setting.

Laser cutting is used in signage, architecture, automotive, and custom fabrication. The primary goal is to cut through material to create shapes or ready-to-assemble parts. Laser cutters use higher power for full penetration.

Laser Engravers: Surface-Level Design

A laser engraver marks, etches, or engraves designs onto the surface of a material. Instead of cutting through, the laser removes a thin surface layer to create text, logos, or artwork.

Laser engraving customizes items like trophies, jewelry, glassware, and more. Engravers prioritize detail, resolution, and contrast over depth of field. Lower power prevents damage to the item's integrity.

Combination Machines

Some machines can perform both cutting and engraving by adjusting the laser power and speed. These are popular with small businesses and hobbyists for their versatility. For large or precise work, dedicated machines offer better results.

Contact Us

In summary, laser cutters cut through materials; laser engravers mark surfaces. Knowing the difference ensures you select the right tool for efficiency and quality.

Learn more about the services that we can offer you by calling us at (972)848-7790 or click here to connect with us online.

Frequently Asked Laser Engraving Questions and Answers

Laser engraving has become increasingly popular across a wide range of industries—from personalized gifts and signage to industrial marking and product branding. Whether you're a business owner, crafter, or someone looking to personalize an item, you may have questions about the process.

Laser engraving has become increasingly popular across a wide range of industries—from personalized gifts and signage to industrial marking and product branding. Whether you're a business owner, crafter, or someone looking to personalize an item, you may have questions about the process. This article addresses some of the most frequently asked questions about laser engraving, with a special focus on services in Dallas, Texas.

1. What materials can be laser-engraved?

One of the most common questions we receive is about material compatibility. Laser engraving works well on a variety of materials, including:

Wood

Acrylic

Glass

Metal (anodized aluminum, stainless steel)

Leather

Plastics

Stone and marble

Each material may require different laser settings, so it's essential to consult a professional. Local experts in Dallas, Texas, Laser Engraving can help you determine the best approach for your specific material.

2. Is laser engraving permanent?

Yes, White Dog laser engraving is a permanent marking method. Unlike printed or painted designs, engravings do not fade or wear away easily. This makes it ideal for items that need to withstand time and use, such as awards, tools, and ID tags.

3. How detailed can a laser engraving be?

Laser engravers are capable of extremely high precision, often down to fractions of a millimeter. You can achieve intricate designs, text, logos, and even photographic images, depending on the resolution and material. High-quality providers in Dallas, Texas, Laser Engraving can ensure your designs are crisp and accurate.

4. Is there a size limit for engraving?

Laser machines come in various sizes, so the size limit depends on the equipment being used. Most local shops can engrave items ranging from small jewelry pieces to large plaques or signage. For oversized or irregular items, custom setups may be necessary.

5. How long does the engraving process take?

Turnaround time varies based on the complexity of the design and the number of items being engraved. Simple jobs can be completed in as little as a few minutes, while bulk or custom orders may take a few days to complete. Most Dallas, Texas Laser Engraving shops offer quick turnaround and same-day service when possible.

6. Can I bring my item to be engraved?

Yes, many laser engraving businesses allow customers to bring in their items. However, it's crucial to confirm the material is safe for laser use. Some plastics, for instance, can release toxic fumes when engraved. Always check with your local Dallas, Texas Laser Engraving provider before bringing in personal items.

7. How much does laser engraving cost?

Pricing varies depending on the material, size, and complexity of the engraving. Basic engravings typically start at around $10–$20, while detailed or bulk projects will incur higher costs. Local providers in Dallas, Texas, Offering Laser Engraving often provide competitive pricing and custom quotes tailored to your specific needs.

If you're in the Dallas area and looking to personalize gifts, brand your business, or create custom items, laser engraving is a reliable and professional solution. Whether you have a single item or a large order, local Dallas, Texas Laser Engraving professionals can guide you through the process and deliver high-quality results.

Learn more about our laser engraving services by calling us at (972)848-7790 or click here to connect with us online.

Can You Engrave Glass and Mugs with a Laser?

Yes, you can engrave glass and mugs with a laser, and it's one of the most popular methods for customizing drinkware. Laser engraving is a precise, clean, and permanent method for creating designs, logos, names, or messages on glass surfaces without the use of ink or decals.

Yes, you can engrave glass and mugs with a laser, and it's one of the most popular methods for customizing drinkware. Laser engraving is a precise, clean, and permanent method for creating designs, logos, names, or messages on glass surfaces without the use of ink or decals.

When it comes to glass and mugs, CO₂ lasers are typically used because they emit a wavelength that interacts well with non-metallic surfaces, such as glass. During the process, the laser gently fractures the glass surface, creating a frosted, etched appearance. This technique is commonly used for wine glasses, beer mugs, coffee cups, and awards.

Not All Glass Is Created Equal

Some types, like tempered glass or glass with internal stress, may crack or chip during the engraving process. That's why it's essential to use the correct settings, tools, and preparation. A laser-safe marking spray or masking tape is often applied beforehand to protect the glass and improve engraving quality.

Ceramic mugs can also be laser-engraved, though they are sometimes coated with glazes that react differently to laser energy. In some cases, removing the coating with a laser reveals the underlying ceramic, resulting in a two-tone design.

The Benefits of Laser Engraving

Laser engraving is highly favored for promotional products, gifts, and wedding favors because it produces elegant results with high precision. It's also durable—engraved designs won't fade, peel, or wash off over time.

In short, laser engraving is an excellent option for personalizing glass and mugs. Ensure you work with an experienced engraver or shop that understands how to handle and process various materials for optimal results.

To get an engraving quote contact us today at (972)848-7790 or click here!

What does an engraving project cost?

When considering personalized gifts, business branding, or custom signage, many people ask, "Is engraving expensive?" The answer depends on several factors, including the material, the design size, and the engraving complexity. Fortunately, in cities like Plano, Irving, Richardson, Frisco, and Garland, Texas, there are a variety of affordable engraving services that cater to a wide range of budgets.

When considering personalized gifts, business branding, or custom signage, many people ask, “Is engraving expensive?” The answer depends on several factors, including the material, the size of the design, and the complexity of the engraving. Fortunately, in cities like Plano, Irving, Richardson, Frisco, and Garland, Texas, there are a variety of affordable engraving services that cater to a wide range of budgets.

Factors That Affect the Cost of Engraving

Material Being Engraved

The type of material greatly influences the price. Engraving on metals like stainless steel or brass typically costs more than engraving on wood or plastic. However, materials like acrylic and leather are often very affordable and still deliver a high-end look.Size and Complexity

A simple name engraved on a trophy will cost much less than a detailed company logo or multi-line message. The more intricate the design and the larger the surface area, the higher the price due to increased time and laser power needed.Type of Engraving Method

Laser engraving is one of the most cost-effective methods because it’s fast, precise, and requires less manual labor. Hand engraving, on the other hand, can be more expensive due to the skill and time involved.Quantity Ordered

Ordering multiple pieces usually reduces the price per item. Businesses in Richardson or Frisco looking to engrave company awards or branded merchandise can benefit from bulk discounts offered by local engraving shops.

Affordable Engraving Options in North Texas

In areas like Plano, Irving, and Garland, residents and business owners have access to competitive engraving services for items such as:

Custom gifts (keychains, flasks, frames)

Trophies and awards

Office signage and nameplates

Promotional items

Wedding accessories and keepsakes

Most local engraving shops in Garland and Richardson offer transparent pricing and quick turnarounds. A simple engraving job can cost as little as $10–$20, while more elaborate or custom work might range from $50 to $200 depending on specifications.

Tips for Getting the Best Value

Shop Local: Plano and Irving have several reputable engraving businesses that can offer same-day or next-day services, saving you on shipping costs and time.

Get a Quote: Always request a quote before placing an order, especially for custom or bulk projects.

Ask About Material Compatibility: Some materials engrave better than others. Your local engraver in Frisco or Garland can recommend the most cost-effective options based on your needs.

Contact Us

Engraving doesn't have to break the bank. Whether you're personalizing a gift in Richardson or ordering branded products for a business in Plano, affordable engraving options are available throughout North Texas. With competitive pricing, fast service, and endless customization opportunities, engraving remains a budget-friendly way to add a unique, lasting touch.

If you're located in Plano, Irving, Richardson, Frisco, or Garland and are considering engraving services, contact your local expert to discuss your ideas and get a personalized quote today.

For an engraving quote, or to learn more about our services, contact us today by calling (972)848-7790 or click here to connect with us online.

Why Local Engraving Services Matter in the Dallas Suburbs

When it comes to personalization, branding, or commemorating special moments, custom engraving is a timeless solution. Whether you're looking to engrave trophies, plaques, jewelry, business signage, or promotional items, choosing a local engraving company offers numerous advantages—especially if you live in cities like Arlington, Plano, Irving, Richardson, Garland, Frisco, McKinney, Carrollton, Grand Prairie, or Mesquite.

When it comes to personalization, branding, or commemorating special moments, custom engraving is a timeless solution. Whether you're looking to engrave trophies, plaques, jewelry, business signage, or promotional items, choosing a local engraving company offers numerous advantages—especially if you live in cities like Arlington, Plano, Irving, Richardson, Garland, Frisco, McKinney, Carrollton, Grand Prairie, or Mesquite.

Fast Turnaround and Personalized Service

One of the most significant benefits of choosing a local engraver is quick turnaround. Instead of waiting for online orders to ship or dealing with customer service reps in other time zones, residents in Arlington, Grand Prairie, and Irving can enjoy the ease of walking into a local shop and discussing their project in person. This is especially helpful for last-minute engraving needs, such as corporate events, sports tournaments, or gifts.

Expertise in a Variety of Materials

Engraving isn't one-size-fits-all. Local professionals in Plano, Frisco, and McKinney often have years of experience working with a wide range of materials, including metal, glass, wood, acrylic, leather, and more. Whether you're creating a custom award plaque or laser-engraving a stainless steel tumbler, a nearby expert can recommend the best technique for durability and appearance.

Supporting Local Business

Choosing a local engraving shop in Garland, Mesquite, or Carrollton not only ensures quality but also supports small businesses in your community. These businesses reinvest in the local economy, provide jobs, and offer a level of customer service that's hard to match online. Many even offer discounts for schools, churches, and nonprofit organizations in the area.

Customization Without Limits

Local engravers offer a wide range of customization options—from precision laser engraving to traditional rotary techniques. Whether you're designing a personalized wedding gift or branding company merchandise in Richardson or Frisco, local shops are equipped to handle unique requests and intricate designs. Some even offer on-site graphic design support to help bring your vision to life.

Convenience and Reliability

Engraving companies in McKinney and Carrollton often provide same-day or next-day services, making them ideal for urgent orders. You can also view product samples in person, ensuring that the final result meets your expectations. Additionally, if any adjustments are needed, it's easier to handle revisions locally than through an online vendor.

Contact Us

Whether you're in Arlington, Plano, Irving, Richardson, Garland, Frisco, McKinney, Carrollton, Grand Prairie, or Mesquite, choosing a local engraving company offers speed, quality, and personal service. From custom gifts to professional signage, working with a local expert ensures your engraved items stand out—and last.

To learn more about our engraving service contact us today by clicking here or calling (972)848-7790.

Why Choose an Engraving Company in 2025?

In 2025, personalized and custom-crafted products will be more popular than ever. From gifts and awards to business signage and industrial tags, the demand for precision and quality has made professional engraving services increasingly essential.

In 2025, personalized and custom-crafted products will be more popular than ever. From gifts and awards to business signage and industrial tags, the demand for precision and quality has made professional engraving services increasingly essential. But with DIY laser tools and online personalization apps gaining traction, why should you still choose a dedicated engraving company in 2025? The answer lies in expertise, technology, and the value of true craftsmanship.

1. Advanced Equipment for Better Results

Engraving companies in 2025 are equipped with cutting-edge laser and rotary machines that offer unmatched precision and speed. These tools enable intricate designs on a wide range of materials, including metal, wood, glass, acrylic, leather, and even stone. Unlike consumer-grade machines or third-party marketplaces, a professional engraving company can handle complex jobs with accuracy and consistency. Whether it's a custom award plaque, serial-numbered asset tags, or branded promotional products, the results are clean, sharp, and professional.

2. Expert Guidance and Design Support

Working with an engraving company gives you access to experienced designers and technicians who can help bring your ideas to life. From font selection and layout to choosing the right material and finish, professionals offer valuable insights that ensure your project looks its best. This hands-on service is essential for commemorative items, gifts, and branding projects where attention to detail matters.

In 2025, personalization is about more than just printing a name—it's about storytelling, identity, and emotion. Engraving experts understand how to capture those elements in their work.

3. Versatility for Personal and Business Needs

An engraving company can serve a diverse range of industries and applications. Whether you're a couple looking to customize wedding décor, a manufacturer needing durable equipment tags, or a business ordering branded signage and nameplates, professional engravers offer services that go far beyond basic personalization.

In particular, industries such as healthcare, aerospace, and manufacturing often rely on engraved labels and parts that must meet safety, compliance, or durability standards—something that only a certified engraving company can consistently deliver.

4. Time and Cost Efficiency

While DIY tools may seem cheaper upfront, mistakes and material waste can add up quickly. Engraving companies save you time and money by delivering high-quality work on the first try. Many offer fast turnaround times, bulk discounts, and streamlined digital ordering systems that simplify the process. In 2025, when speed and precision are essential for both personal and professional projects, the efficiency of a skilled engraver is a valuable asset.

5. Customization Trends Are Evolving

As consumer expectations grow, so do the options for customization. In 2025, engraving companies offer innovative services such as color filling, deep etching, 3D engraving, and even augmented reality integration on engraved items. These creative capabilities enable the creation of more dynamic and interactive pieces—something that most DIY solutions can't replicate.

Contact Us

In an era where customization is king, choosing a professional engraving company ensures your project stands out. With the right mix of modern technology, expert craftsmanship, and reliable service, engraving companies in 2025 are more valuable than ever. Whether you're marking a milestone, promoting a brand, or producing industrial parts, their work leaves a lasting impression—literally and figuratively.

Get an engraving quote today by calling us at (972) 848-7790 or click here to connect with us online.

Laser vs. Hand Engraving: Which is Right for Your Project?

Engraving is a timeless craft that adds a personal touch to everything from gifts and awards to industrial parts and signage. When it comes to choosing the best engraving method, two popular options often come up: laser engraving and hand engraving. Both have unique benefits and distinct characteristics, but which one is right for your project? Let’s break down the differences, advantages, and ideal uses for each method.

Engraving is a timeless craft that adds a personal touch to everything from gifts and awards to industrial parts and signage. When it comes to choosing the best engraving method, two popular options often come up: laser engraving and hand engraving. Both have unique benefits and distinct characteristics, but which one is right for your project? Let’s break down the differences, advantages, and ideal uses for each method.

What is Laser Engraving?

Laser engraving utilizes a high-powered, focused beam of light to etch designs onto various materials, including wood, metal, glass, acrylic, and leather. The laser vaporizes the surface layer, leaving a precise, permanent mark. This technique is computer-controlled, allowing for incredible detail and consistency even on complex designs.

Advantages of Laser Engraving

Precision and Detail: Laser engraving excels at intricate patterns, fine text, and detailed logos that might be difficult or impossible to achieve by hand.

Speed and Efficiency: Since it’s automated, laser engraving can produce large quantities quickly and consistently, eliminating fatigue and variation.

Versatility: It works on a broad range of materials, including metals, plastics, wood, glass, and more.

Cost-Effective for Bulk: For businesses or projects that require many identical engravings, laser engraving is often more cost-effective per piece.

Non-Contact Process: Because the laser doesn’t physically touch the material, there is minimal risk of damaging delicate items.

What is Hand Engraving?

Hand engraving is a traditional, White Dog manual method in which skilled artisans use specialized tools, such as gravers or burins, to carve designs directly into the material. This technique requires a high level of craftsmanship and is often regarded as an art form.

Advantages of Hand Engraving

Unique, Personal Touch: Each hand-engraved piece is one of a kind, bearing the subtle marks and personality of the artist.

Depth and Texture: Hand engraving can create deeper cuts and varied textures, adding tactile richness and visual depth.

Ideal for Customization: Small, detailed custom work — especially on curved or irregular surfaces — can be easier to manage by hand.

Artistic Value: Hand engraving is prized for heirloom quality and craftsmanship, often increasing the sentimental or monetary value of an item.

Which Should You Choose?

Consider Your Project’s Purpose

If you need mass production or highly detailed, repeatable designs on standard shapes and flat surfaces, laser engraving is likely the best fit.

If you want a unique, artistic piece with handcrafted charm, or you’re working on irregular or precious materials, hand engraving offers a timeless appeal.

Material Matters

Laser engraving works well on metals such as stainless steel, aluminum, brass, and anodized surfaces, as well as non-metals like wood and glass.

Hand engraving is typically preferred on precious metals (silver, gold), fine jewelry, watches, and customized gifts where artistry matters most.

Budget and Timeline

Laser engraving generally offers faster turnaround and lower costs for larger runs.

Hand engraving can be more expensive and time-consuming, but it justifies the price due to its artistry and exclusivity.

Contact Us

Both laser and hand engraving have their own strengths and ideal applications. If you value speed, precision, and scalability, laser engraving is an excellent choice. But if you want a handcrafted, unique piece imbued with character and tradition, hand engraving is unmatched.

Understanding your project’s goals, material, budget, and desired aesthetic will guide you to the proper engraving method. Whether you choose laser or hand engraving, the result will be a meaningful, personalized creation that stands the test of time.

To get an engraving quote, contact us today by calling (972) 848-7790 or click here to connect with us online.

The Best Laser Engraved Products to Sell Online in 2025

Laser engraving is a booming market in the world of customized and handmade products. Thanks to its versatility and high-precision detailing, laser engraving offers entrepreneurs and crafters a profitable way to create and sell unique items online.

Laser engraving is a booming market in the world of customized and handmade products. Thanks to its versatility and high-precision detailing, laser engraving offers entrepreneurs and crafters a profitable way to create and sell unique items online. If you're considering entering the market or expanding your product line, here are the top laser-engraved products to sell online right now.

1. Personalized Cutting Boards

Custom engraved cutting boards are a top seller across platforms like Etsy and Amazon Handmade. They're especially popular for weddings, anniversaries, housewarming gifts, and holidays. You can engrave family names, recipes, coordinates, or even detailed artwork. Bamboo and hardwood boards are durable, engrave well, and photograph beautifully for online listings.

2. Custom Tumblers and Water Bottles

Laser-engraved stainless steel tumblers are a popular choice among people of all ages. Brands like YETI and Hydro Flask are often customized with names, logos, or inspirational quotes. This product line is ideal for events, corporate gifts, or promotional giveaways. Their long shelf life and broad appeal make them an excellent repeat seller.

3. Pet Tags and Accessories

Pet lovers are always looking for ways to personalize their furry friend's gear. Laser-engraved pet tags, made from metal, acrylic, or wood, are both functional and stylish. You can also branch out into engraved pet collar nameplates, leash hooks, and personalized bowls.

4. Keychains and Bag Tags

These small, affordable items are perfect for bulk orders and impulse buys. Keychains with initials, names, special dates, or coordinates make great souvenirs and wedding favors. Materials like wood, leather, and acrylic are lightweight, cost-effective, and can be engraved cleanly.

5. Wedding and Event Decor

Laser-cut and engraved items for weddings and events are high-margin and in constant demand. Think custom cake toppers, guestbook covers, table numbers, signage, and name place cards. These are ideal for customers who want elegant, personal touches without incurring a high cost.

6. Phone Stands and Desk Accessories

With remote work becoming the norm, personalized workspace accessories are gaining popularity. Items like engraved wooden phone stands, monitor risers, coasters, and pen holders sell well—mainly when targeted to specific niches, such as teachers, tech workers, or gamers.

7. Jewelry and Keepsake Boxes

People love keepsakes, and engraved boxes add emotional value to functional storage. Whether it's a ring box for a proposal or a memory box for a child, the engraving gives a personal touch that makes these items timeless.

Tips for Success

Offer Customization: Personalization is what makes engraved products sell. Provide customers with options to add names, messages, or designs.

High-Quality Photos: Showcase your products with professional, well-lit images that capture their true essence. Include close-ups of engraving details.

Target Specific Occasions: Tailor products for weddings, holidays, baby showers, graduations, and corporate events to increase seasonal traffic.

Laser engraving offers a world of possibilities for online sellers. Whether you're running a side hustle or a full-scale operation, choosing the right products and marketing them effectively can turn your creativity into a thriving business.

Learn more about the leaser engraving services that we can offer you by calling us at (972) 848-7790 or click here to connect with us online.

What Is Laser Engraving?

Laser engraving is a modern and precise method of etching or marking the surface of an object using a focused beam of light. This process removes material from the surface to create a permanent design, text, or image. It’s widely used in industries ranging from manufacturing and electronics to jewelry and arts due to its accuracy, durability, and versatility.

Laser engraving is a modern and precise method of etching or marking the surface of an object using a focused beam of light. This process removes material from the surface to create a permanent design, text, or image. It’s widely used in industries ranging from manufacturing and electronics to jewelry and arts due to its accuracy, durability, and versatility.

At its core, laser engraving involves a high-powered laser beam directed at a material. This beam generates intense heat, which vaporizes the surface layer of the material, leaving behind a visible mark. Unlike traditional engraving methods that use sharp tools to physically cut into a surface, laser engraving is non-contact. This means there’s no direct mechanical pressure on the item, which minimizes the risk of damage or distortion.

About Laser Engraving

Laser engraving is often confused with laser etching and laser marking. While these terms are sometimes used interchangeably, they represent slightly different processes. Laser etching melts the surface of the material rather than vaporizing it, creating a raised mark. Laser marking, on the other hand, changes the color of the material without removing any surface. Among these, laser engraving is the most aggressive in terms of depth and permanence.

One of the key benefits of laser engraving is its ability to produce highly detailed and intricate designs. The laser can be precisely controlled by computer software, allowing for the creation of custom images, barcodes, logos, and even photographs. This level of detail makes it ideal for applications like personalized gifts, industrial labeling, and creating fine art.

Materials compatible with laser engraving include wood, metal, glass, acrylic, leather, stone, and certain plastics. The choice of laser—such as CO₂, fiber, or diode—depends on the material being engraved. For instance, CO₂ lasers are commonly used for wood, glass, and leather, while fiber lasers are more suitable for metals and printed plastics.

In addition to being precise, laser engraving is also fast and efficient. Once a design is programmed into the system, the laser can reproduce the same pattern repeatedly with consistent quality. This makes it a popular choice for mass production as well as one-off custom jobs.

Safety is also an important consideration. While laser engravers are generally safe when used properly, the process does involve intense light and potentially harmful fumes, depending on the material. Proper ventilation, safety enclosures, and eye protection are recommended when operating laser engraving equipment.

Superior Precision

In summary, laser engraving is a high-tech method of permanently marking or decorating a wide range of materials using a laser beam. It offers superior precision, versatility, and repeatability compared to traditional engraving methods. Whether for commercial use, artistic expression, or personal customization, laser engraving has become a go-to technology for creating lasting impressions.

Learn more about the laser engraving services that we can offer you by clicking here to connect with us online.